CNC machining

Spanflug is specialized on CNC machining and offers turning, mill-turning and milling parts. We work with a large network of suppliers to completely cover your requirements.

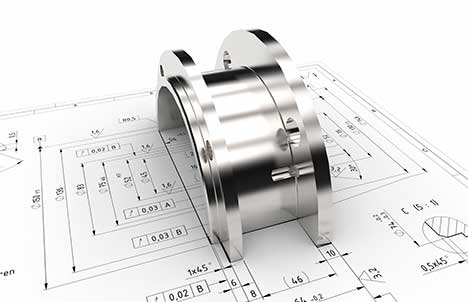

The abbreviation CNC stands for Computerized Numerical Control. This refers to the computerized numerical control of machine tools used in CNC machining. These are also referred to as CNC machines. CNC machining with the help of these machines enables the production of parts with complex geometric shapes and with high precision.

Our offer

- Express production from 5 working days

- Free capacity and the right supplier for your parts

- First class manufacturing in Germany and Austria

- Milling parts: 1 to 1,000 pieces

- Turning parts: 1 up to 200,000 pieces

Steps of CNC machining

1. Preparing the stocks

CNC machining requires prefabricated stocks in various shapes, mainly bars and plates. These stocks are prepared by various cutting processes depending on the quantity, material and dimensions. These cutting processes include sawing, laser cutting, flame cutting and waterjet cutting.

2. Setting up the CNC machine

During setup, a machine tool is prepared for the manufacturing of the CNC part. The most important steps in setup are the clamping of the stock and the preparation of the turning and milling tools. When selecting the clamping, the geometry of the stock and the finished part, the expected machining forces, the accessibility for the tools and the work sequence during CNC machining must be taken into account. Depending on the machining task, finding a technically sensible and economical clamping solution requires a great deal of experience and well-qualified employees. The time required depends largely on the mentioned factors and can vary from a few minutes to several hours. For this reason, clamping can be a cost driver in CNC machining.

3. Programming the CNC machine

The machining program describes how the CNC machine produces the finished part from the stock using cutting tools. These programs can be created directly on the CNC machine controls or with the help of CAM software (Computer Aided Manufacturing software). In general, programming is not automated up to now and requires well-qualified personnel. Advances in both CNC machine controls and CAM software are increasingly simplifying and accelerating programming. The time required depends largely on the geometric complexity of the parts and can range from a few minutes to several hours.

4. Machining

The actual CNC machining takes place after completion of the preparatory steps on CNC lathes, CNC milling machines or on CNC machines capable of both turning and milling. Here you can find more information about the manufacturing processes Turning and Milling. The time required for machining a workpiece is determined by the main processing times of the individual machining steps and auxiliary times, for example for changing the tools and the workpiece. The times required for the individual machining steps depend on many factors, the material and the volume of material to be removed often have the biggest impact.

Our processes in the field of CNC machining

CNC turning parts

Further information about our manufacturing capabilities in the field of CNC turning

CNC milling parts

Further information about our manufacturing capabilities in the field of CNC milling

For which parts is CNC machining suitable?

CNC machining is used primarily when one or more of the following criteria are present:

- Number of pieces: 1 to 10,000: The one-off setup costs are significantly lower compared to other manufacturing processes (e.g. injection molding and deep drawing), so that individual parts can also be manufactured cost-effectively. For small and medium quantities, CNC machining is usually the most economical option. Depending on the material and the part's geometry, CNC machining can also be economical for very high quantities.

- High surface quality: CNC machining achieves a significantly higher surface quality than, for example, 3D printing. Surface quality values in the range of Ra 0.8-3.2 are typical. Values smaller than Ra 0.8 can also be achieved without further machining steps.

- High precision: With CNC machining parts with tighter tolerances can be machined compared to most other manufacturing processes. The achievable geometry deviation is in the range of a few micrometers.

- High mechanical requirements: CNC machining usually does not have a negative impact on the mechanical properties of the machined materials. Moreover, machining of high-strength and hard (even hardened) materials is possible.

- Short delivery time: Thanks to the standardized order processing at Spanflug and the high degree of automation with the help of the CAD files of the components, we can offer CNC components with a delivery time of 5 working days. The one-off set-up costs are significantly lower compared to other manufacturing processes (e.g. injection molding and deep drawing), meaning that individual parts can also be manufactured cost-effectively.

Our expertise

Spanflug's core technology is the automated quoting of manufacturing costs for turning parts and Milling parts. With a team of experts in CNC machining, CAD data analysis and algorithms, Spanflug has developed the fastest and most accurate algorithm for automated quoting of manufacturing costs of CNC parts and is continuously working to improve it. Spanflug's technology is based on in-depth process knowledge, latest research results and decades of practical experience in the field of CNC machining.

Spanflug BUY is the digital procurement solution for turning and milling parts. Registered users have the possibility there to calculate the manufacturing costs of parts immediately. Unlike 3D printing, for example, where there is a simple correlation between the volume of the parts and the costs, there are countless factors to be taken into account in turning and milling that influence the parts price. With Spanflug, these price-relevant influencing factors are automatically read from the CAD model of the part and optionally from an additional technical drawing. Subsequently, our algorithm calculates a market-driven price for the production of your turned and milled parts within a few seconds. The parts can be ordered immediately at this price.