Spanflug Technologies presents the integration of stock prices and availability "in real time" at the AMB in Stuttgart. Users of the Spanflug platform for turning and milling parts have now access to even more precise and up-to-date data. Manufacturing companies furthermore benefit from attractive price conditions when purchasing stocks, while purchasers get price advantages when ordering parts made of specific materials. With the direct integration of the first stock suppliers, Spanflug is creating a new, integrated supply chain and is taking a further step towards more efficiently dovetailing supply and demand on its manufacturing platform.

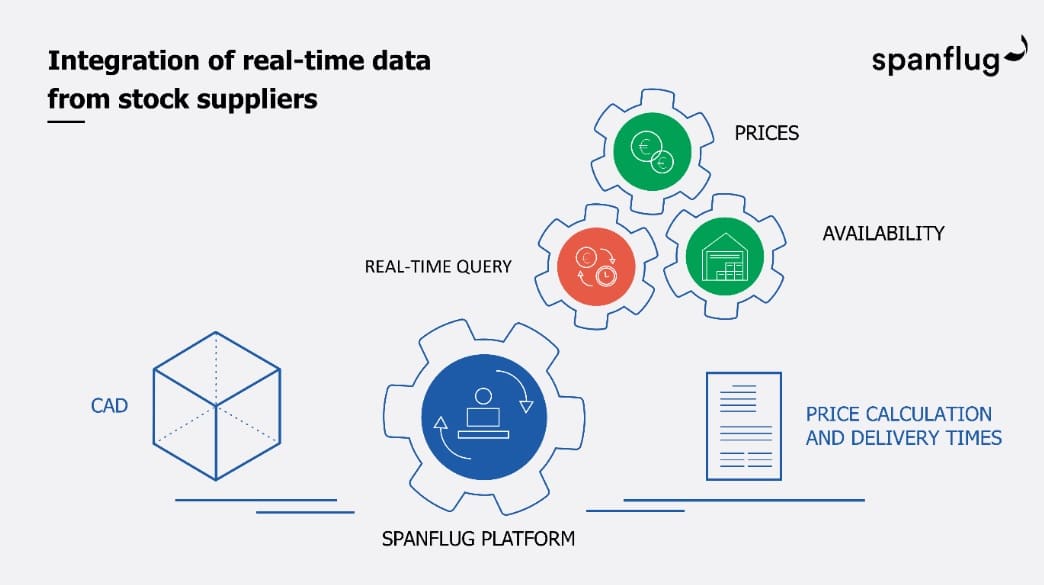

At AMB, the international meeting place for experts in metal cutting (September 13 to 17, Stuttgart, Germany), the technology company Spanflug will present new features of its manufacturing platform for CNC turning and milling parts. The most important innovation and a real added value for users on the purchasing and manufacturing side is the integration of real-time data from stock suppliers into the platform.

Thanks to the cooperation with stock suppliers for parts manufacturing, the Spanflug algorithm can now access up-to-date prices and availabilities from the cooperation partners. This provides a significant advantage, especially in times of frequent and severe price fluctuations as well as volatile supply chains.

With access to this real-time data, technical purchasers uploading CAD models of required parts to the Spanflug online shop for instant quotes, will now benefit from an even more accurate pricing and delivery time calculation.

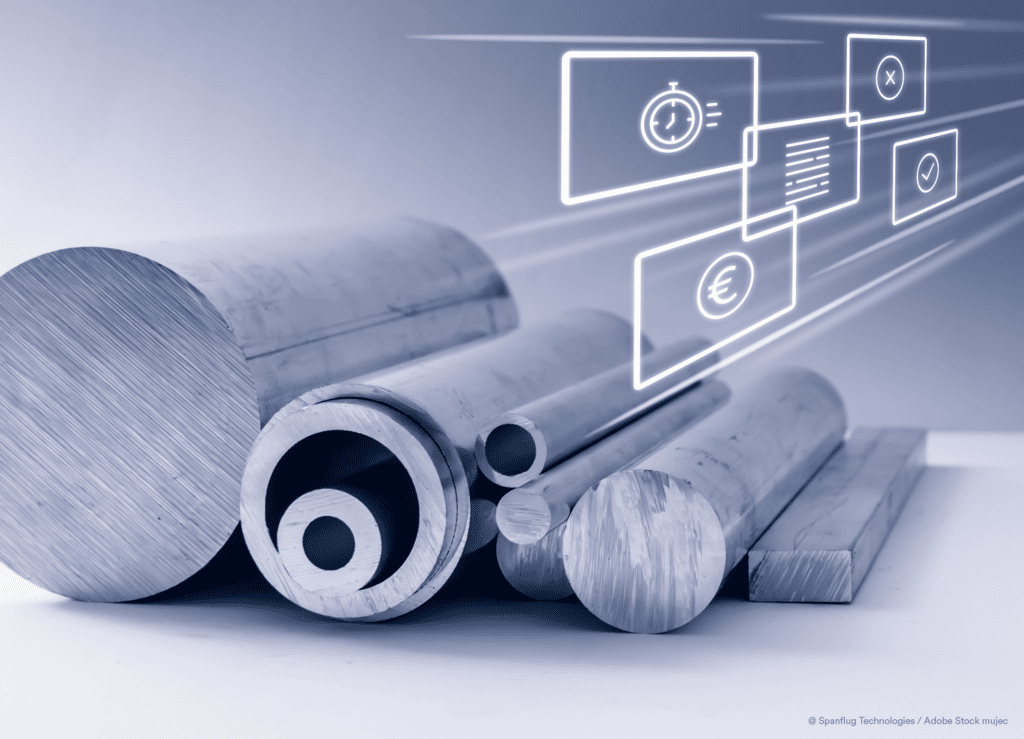

The new integration also offers an interesting added value for CNC manufacturing companies. When accepting orders in the Spanflug supplier portal, they can utilize very attractive purchasing terms and conditions for stock products. Users of Spanflug calculation software also have access to the latest stock data when calculating their quotes. In addition, they can also order, for example, rods, tubes and plates directly via Spanflug at minimum effort.

"We have already been able to integrate data from the first suppliers of aluminum and plastic stocks into our technology. The next partnerships will follow shortly," explains Dr. Markus Westermeier, Managing Director at Spanflug Technologies. "To this end, we are in concrete discussion with further stock suppliers, so that in the future we will be able to support our entire range of over 50 materials with real-time data." Once again, the advantage of the innovative, self-developed Spanflug algorithm becomes apparent. It forms the technical basis for the integration of the stock data sources and enabled a very fast implementation of the first pilot projects.

With the connection of the stock suppliers, Spanflug integrates another step of the supply chain into its manufacturing platform. As a pioneer in the market, the technology provider thus demonstrates how real-time information can make lean, digital procurement processes even more efficient.

The online store for buyers of CNC milled and turned parts, solutions for manufacturing companies and the latest platform enhancements will be presented by Spanflug at AMB Stuttgart, booth 235.4 (East entrance).