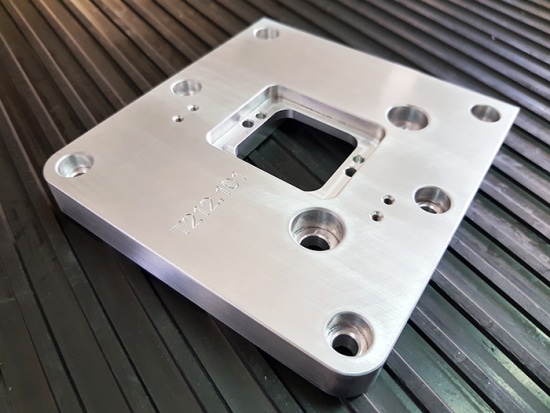

CNC milling parts

How are CNC milling parts machined?

CNC milling parts are machined on CNC milling machines using rotating tools. CNC milling machines exist with different linear and rotational axes configurations: 3-axis, 4-axis and 5-axis milling machines.

3-axis milling machines can machine CNC milling parts from one accessibility direction only. They are less expensive than the other types of milling machines. 4-axis milling machines have an additional rotational axis, for example for machining spindles and helical geometries. 5-axis milling machines can machine CNC milling parts from all sides, depending on the clamping, and can also machine complex geometries.

With our network of suppliers, we can manufacture a wide range of CNC milling parts for a variety of requirements.

Spanflug is specialized in CNC machining and can process parts with the following properties. We constantly extend the capabilities of our instant pricing engine.

CNC machining capabilities for milling parts

- Part dimensions from 2 mm x 2 mm x 2 mm

- Part dimensions up to 3,000 mm x 2,000 mm x 200 mm

- Larger components on request

- Manufacturing up to an accuracy of 5 µm

- 1 - 1,000 units via Spanflug BUY, larger quantities on request

- 3-axis, 4-axis and 5-axis milling

- Surface quality values down to Ra 0.4

- Parts with complex surfaces, like molds and dies

- CNC milling parts from over 60 Materials

- More than 30 post-treatments

How easy it is to order your milled part with Spanflug BUY

- Upload CAD file (and optionally a technical drawing)

- Configure part

- Calculate instant quote

- Order part

Project RFQs

Here to help

For larger part packages, series parts and call-off orders, we will be happy to provide you with an individual quotation. Here you can send us your project RFQ quickly and easily.

If you have any questions or would like to schedule an individual consultation, please do not hesitate to contact us.