Out of the comfort zone, creating competitive advantage

Case study: Schwab CNC uses Spanflug to automatically calculate manufacturing times and costs for parts, making the business more competitive.

How Schwab CNC is tapping into new customer segments thanks to Spanflug MAKE

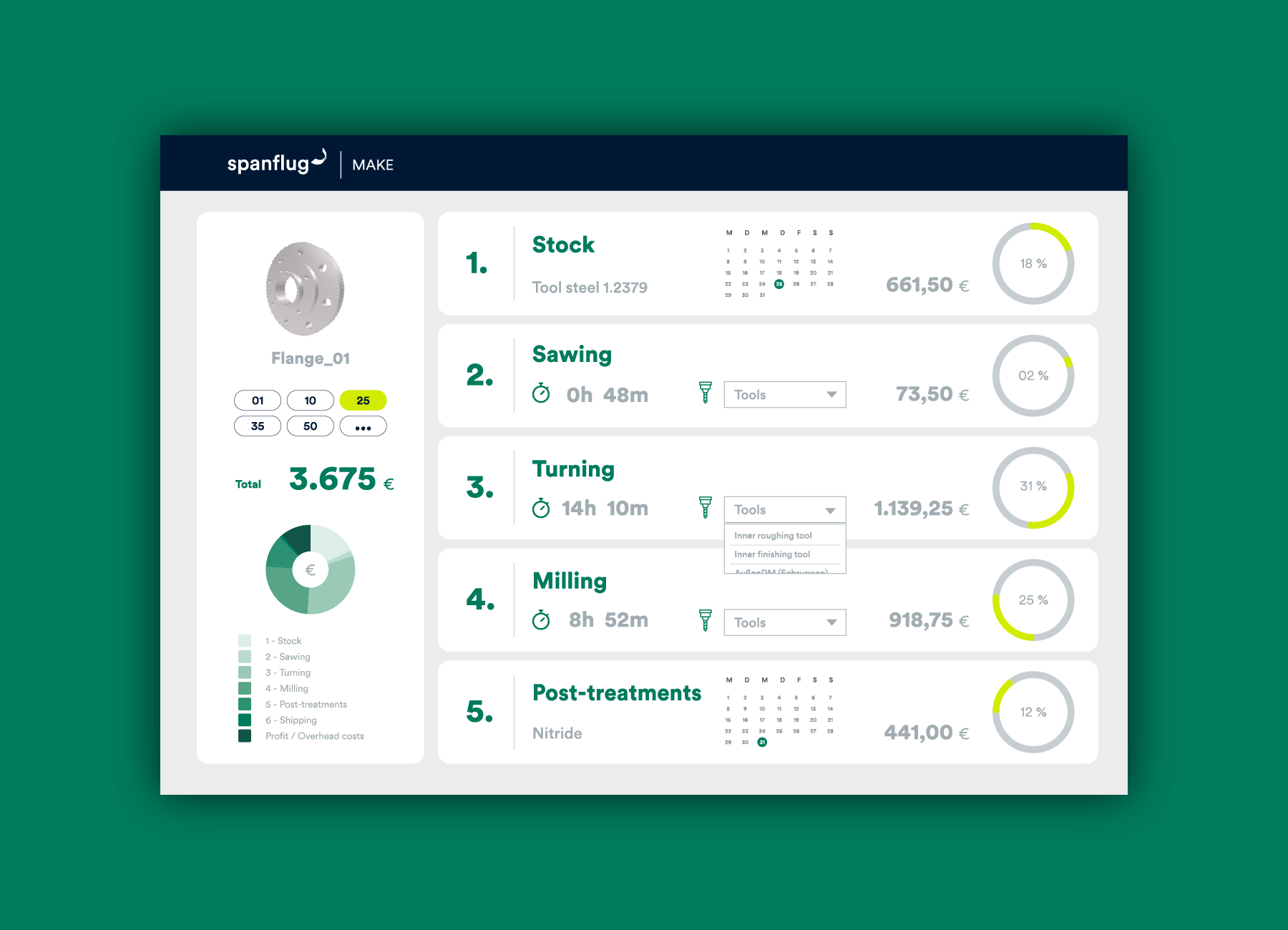

The current challenges for manufacturers in the automotive supply industry are enormous. They have to adapt to new customers and to parts that are outside their specialization. In order to increase its own efficiency, reduce costs and position itself more competitively, Schwab CNC Metallbearbeitung is increasingly focusing on digitalization and automation, for example with Spanflug MAKE. The quoting software enables the CNC machine shop to automatically calculate manufacturing times and costs, to create quotes with just a few mouse clicks and to determine the most economical manufacturing process.

Picture: Markus Schwab (left) and Reiner Schwab (right)

The company

“The market and the parts we manufacture for our customers change from year to year,” observes Markus Schwab, who runs Schwab CNC Metallbearbeitung eK together with his father Reiner. When Reiner Schwab founded the company in 2010 in Rot am See, Baden-Württemberg, Germany, the order intake was very homogeneous. “We mainly manufactured series parts for combustion engines and for the automotive aftermarket,” he reports. However, the industry has changed massively in recent years as a result of electromobility–and with it the order intake for suppliers like Schwab: the demand for pre-series parts increased. In addition, the company received more RFQs for parts for the mechanical engineering industry.

“While series production focuses on price and maximum quality, pre-series production requires flexibility above all,” says Markus Schwab, describing the situation. However, demand from the automotive industry is currently declining significantly and, according to the machine shop, a particularly large number of development projects are currently being stopped or postponed. For Schwab, this means that the company must position itself more broadly in order to be able to react quickly to the rapidly changing market.

Tapping safely into new worlds

“In future, in addition to large projects with complex parts or series, we want to grow the share of smaller orders,” says Managing Director Markus Schwab, explaining his strategy. “Competition is increasing. For us, this means manufacturing parts with which we have hardly any experience. So we have to get out of our comfort zone.” One of the challenges of this new approach is in quoting, in particular the ability to win the customer order with a precise quote that is in line with the market and competitive, and at the same time profitable for the supplier. “Even for parts that lie outside the company’s own specialization, the calculation should be sound and reliable”.

The implementation of digital technologies offers immense potential to increase efficiency, reduce costs and to stay competitive. Schwab CNC therefore evaluated various software tools for different tasks. An immediate insight in this process: solutions to automate business processes such as quoting, work preparation or support in sales not only have just as much efficiency potential as the automation of manufacturing itself. They are also easier and faster to implement.

Respond to customer inquiries more quickly

Markus Schwab still remembers the key experience that quickly turned the father-son business into a Spanflug customer: “We had a customer inquiry including over 40 very different parts forming an assembly, parts with which we had little experience. We only had two days to prepare a quote. In a conversation with a sales employee from one of our tool suppliers, he told us about the quoting software Spanflug MAKE.

We registered straight away and were quickly convinced that the software could help us enormously with calculation and preparing quotes,” says Markus Schwab. “Based on the CAD models and 2D drawings we uploaded, we were able to calculate manufacturing times and costs for both simple and complex turning and milling parts for the entire project in one go.”

Before Spanflug, many manual work steps were needed for quoting, as Schwab reports: “Depending on the complexity, we had to print the drawing, edit it to match the CAD model and target geometry, search for the stock needed and – if not available in our warehouse – request prices from the stock supplier. We then had to assess and calculate the scope of machining and write the quote.” With the quoting solution, he now calculates costs and prices in line with the market automatically, including batch quantities. The quote can then be generated as ready-to-send PDF document with just a few clicks.

Reiner Schwab emphasizes the importance of accurate quotes for the business success: “If we take too much time to reply to RFQs, there is always a risk that the customer will place the order with a different supplier. If we calculate prices below our profitability threshold to make sure we win the order, this can quickly become risky, especially with large orders.”

Schwab CNC

Based on the CAD models and technical drawings we uploaded, we were able to calculate manufacturing times and costs for simple and complex turning and milling parts for the entire project in one go.

Less effort during quoting and work preparation

Senior manager Reiner Schwab shares his experience of the easy start with the cloud-based Software-as-a-Service solution Spanflug MAKE: “We were able to start with the solution intuitively. The results with the standard calculation settings were already very close to our operational reality, and we finetuned the rest to match our needs using the slider controls.” For series parts that are usually run on the machines, Schwab CNC has slightly longer setup times. While no training phase with ones own database is needed, Spanflug MAKE offers options to customize the calculation with a few clicks – starting from setting up the own machine park to adjusting spindle speed or process times for programming, set-up and machining.

Spanflug MAKE automatically analyzes parts in seconds, determining the most economical manufacturing process and all the needed stocks and tools. Based on this, the software automatically generates a calculation proposal, from which a ready-to-send quote can be generated, and also an operational plan.

“We can now respond to customer inquiries much more quickly and also speed up our work preparation,” emphasizes Reiner Schwab. As early as the quotation phase, the machine shop gets relevant information on the required stocks, tools and post-processing steps in an operational plan, and can start resource planning in the transition to order processing much more quickly and efficiently.

Schwab CNC has already taken advantage of the possibility to procure stocks neeeded for order fulfillment directly via Spanflug. And if requested parts are completely outside of Schwab’s machining capabilities, or if all machines are already working at full capacity, they can be outsourced to Spanflug, ordered through the procurement solution Spanflug BUY and be reliably manufactured in the Spanflug partner network. “This allows us to efficiently outsource the manufacturing of certain parts,” says Reiner Schwab.

Mastering complexity with ease

Recently, Spanflug MAKE began taking individual, near-net-shape stock geometries into account in its automated quotation calculation – another advantage that Schwab CNC welcomes and will continue to test. The company’s customers also include foundries that request castings and preforms to be machined by Schwab and then sell the parts on to tier 1 suppliers or directly to OEMs.

In Spanflug MAKE, users can upload the CAD data of the individual preforms and then automatically calculate the turning and milling operations. Only the volumes and surfaces to be machined are taken into account in the calculation.

Conclusion: the right time for process optimization

The experts for precise CNC metalworking are not unaffected by the current economic situation, but they want to use the moment as an opportunity. Reiner and Markus Schwab want to leverage software solutions such as Spanflug MAKE to further advance digitalization in their company.

“The current situation is ideal for this. Demand is slightly lower overall, so we also have the capacity to evaluate and optimize our internal processes. We want to be ready when the order situation picks up and then take off together with our customers.” The senior partner adds: “I know that my son has a good understanding of the benefits of digitalization and will find solutions that will support us to grow in the long term. I trust him completely when it comes to these issues.”

“The advantages of Spanflug MAKE convinced us,” summarizes his son Markus: “Someone once told me that using tools like Spanflug was for lazy people. I replied: It’s rather smart to rely on such programs. We can complete complex tasks faster and more precisely – after all, it’s about working smarter, not harder.”

Start for free. Benefit immediately.

Your machine shop, too, can benefit from automated quoting. Our software solution Spanflug MAKE is ready to use immediately and delivers precise results. No large database or long training phases are needed. And best of all: you can calculate up to 5 parts per month for free.