Procure easily. Manufacture efficiently.

We connect supply and demand quickly and efficiently on our manufacturing platform. By combining intelligent algorithms, AI, platform technology and manufacturing expertise, we are able to significantly simplify the otherwise time-consuming and complex procurement process for custom machined parts. This allows us to reduce the workload for purchasers and suppliers by up to 90%.

Procure custom parts easily, quickly and reliably

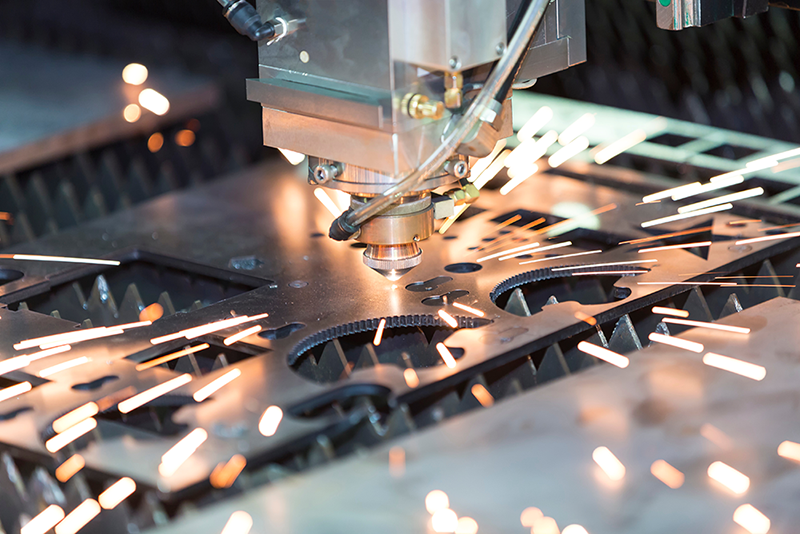

Spanflug BUY is the platform for the efficient procurement of custom parts, such as turning parts, milling parts or laser parts. Through the interaction of automated processes, intelligent algorithms and a network of over 6,000 machines, we find the optimum solution for each of your manufacturing tasks. This makes your purchasers’ life much easier, reduces overall costs by up to 35%, and ensures that your parts are delivered on time and with the quality you need.

Quote efficiently and get more orders as a CNC machine shop

As a CNC machine shop, you can use our automated quoting software Spanflug MAKE to calculate precise manufacturing times and costs, and simplify your entire quoting process. You can also become a manufacturing partner in our network and increase your revenue without any sales effort of your own.

Our customers & partners

What we have achieved

Here are some key facts about our platform. Read our case studies to learn more about how we support our customers.

> 4000

satisfied customers

1 Mio.

calculated parts

90 %

Less effort

35 %

lower total costs

What our customers say about Spanflug

Curious?

Would you like to see how easy it is to use the Spanflug solutions and how quickly you can benefit as a purchaser or CNC machine shop? Try it out for yourself or simply book a product demo with our sales team.