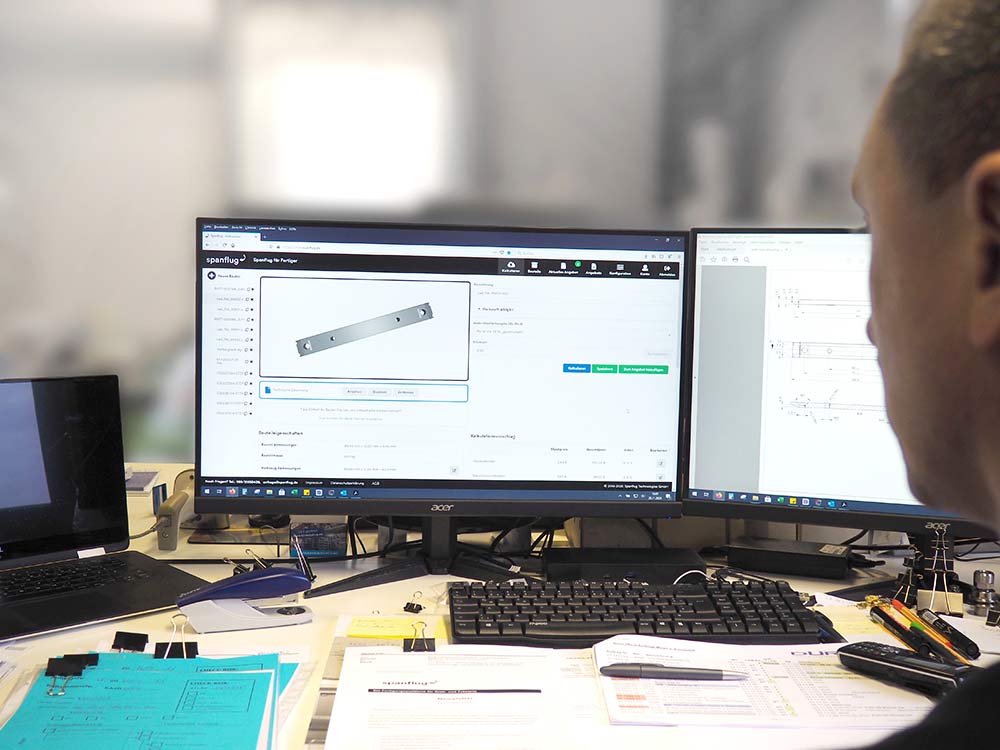

Customer stories and Spanflug references

Since our foundation in 2018, thousands of customers from a wide range of industries have purchased their custom machined parts via Spanflug or have benefited from our quoting software. Here, some of our customers speak about their experience with Spanflug and how our solutions help their companies to become more efficient and competitive.

References at a glance

Read what our customers say about how our fast, automated processes have saved them efforts and money when procuring custom machined parts.

Here’s what the machine shops that use our quoting software or increase their sales as a manufacturing partner in our network are saying.