Successful automation of the quoting process with Spanflug MAKE

Case study: Thanks to Spanflug MAKE, CNC manufacturer Millpol, based in Łódź, Poland, has successfully transitioned to automated and scalable quotation calculation.

About the company

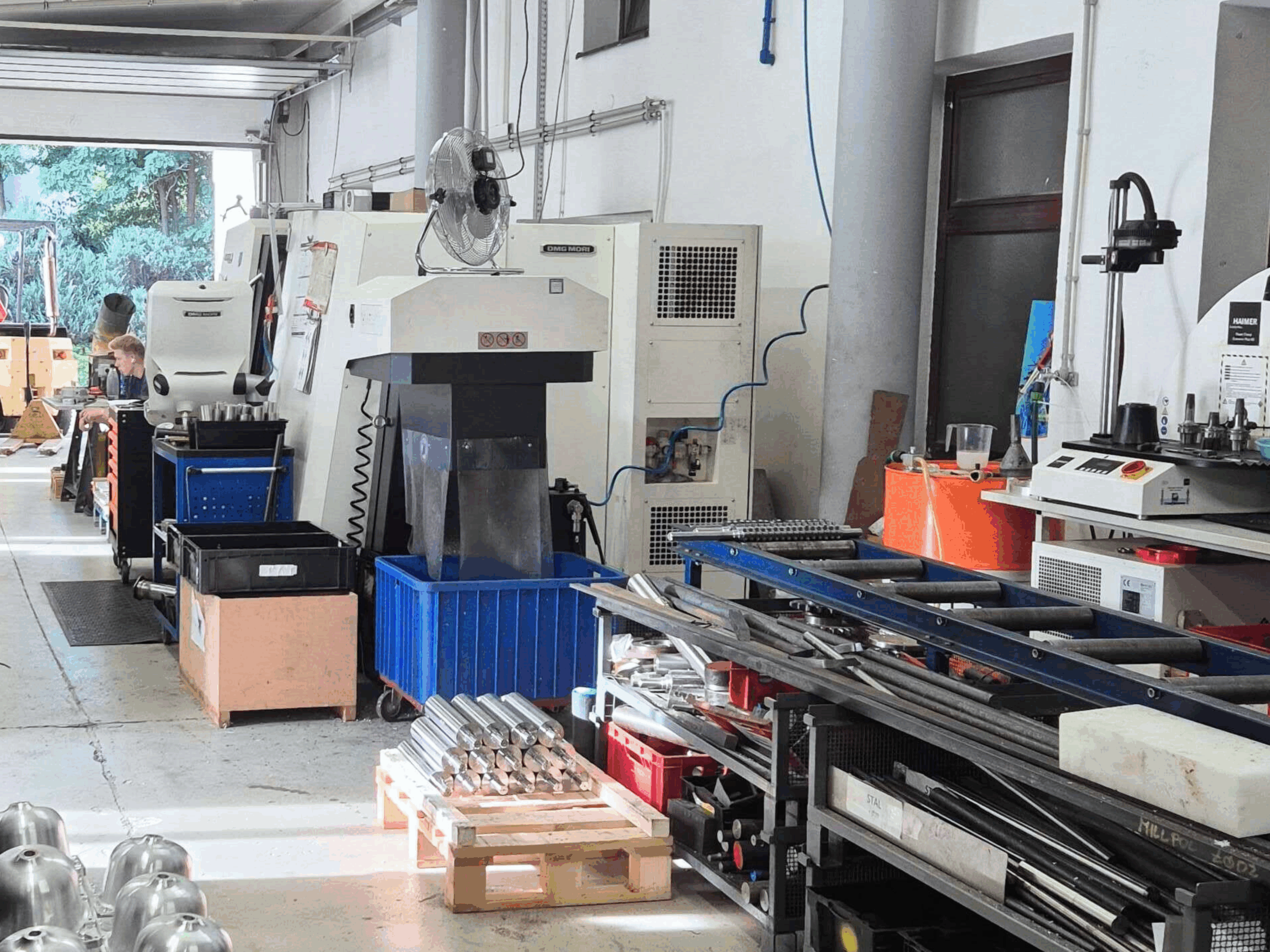

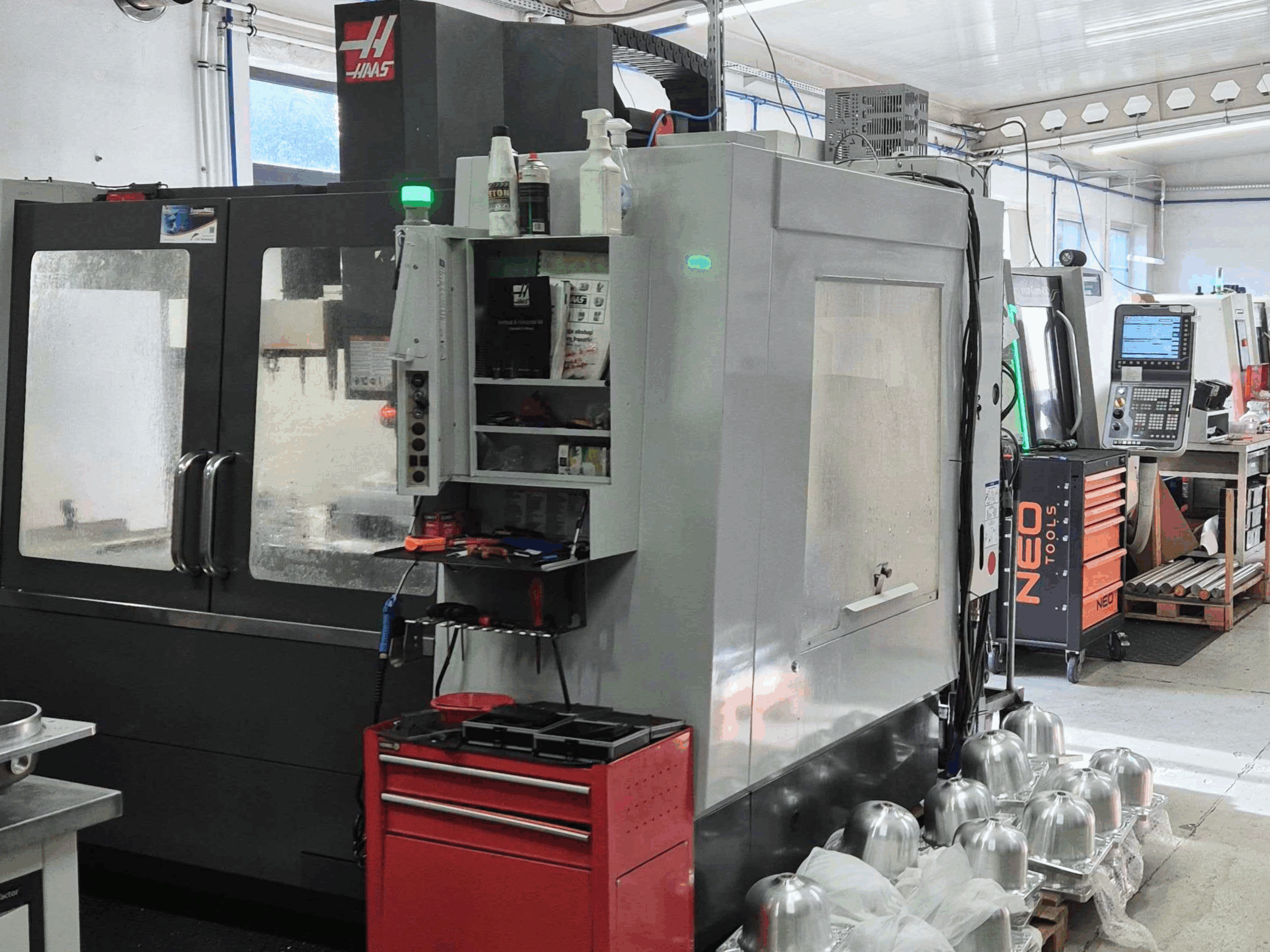

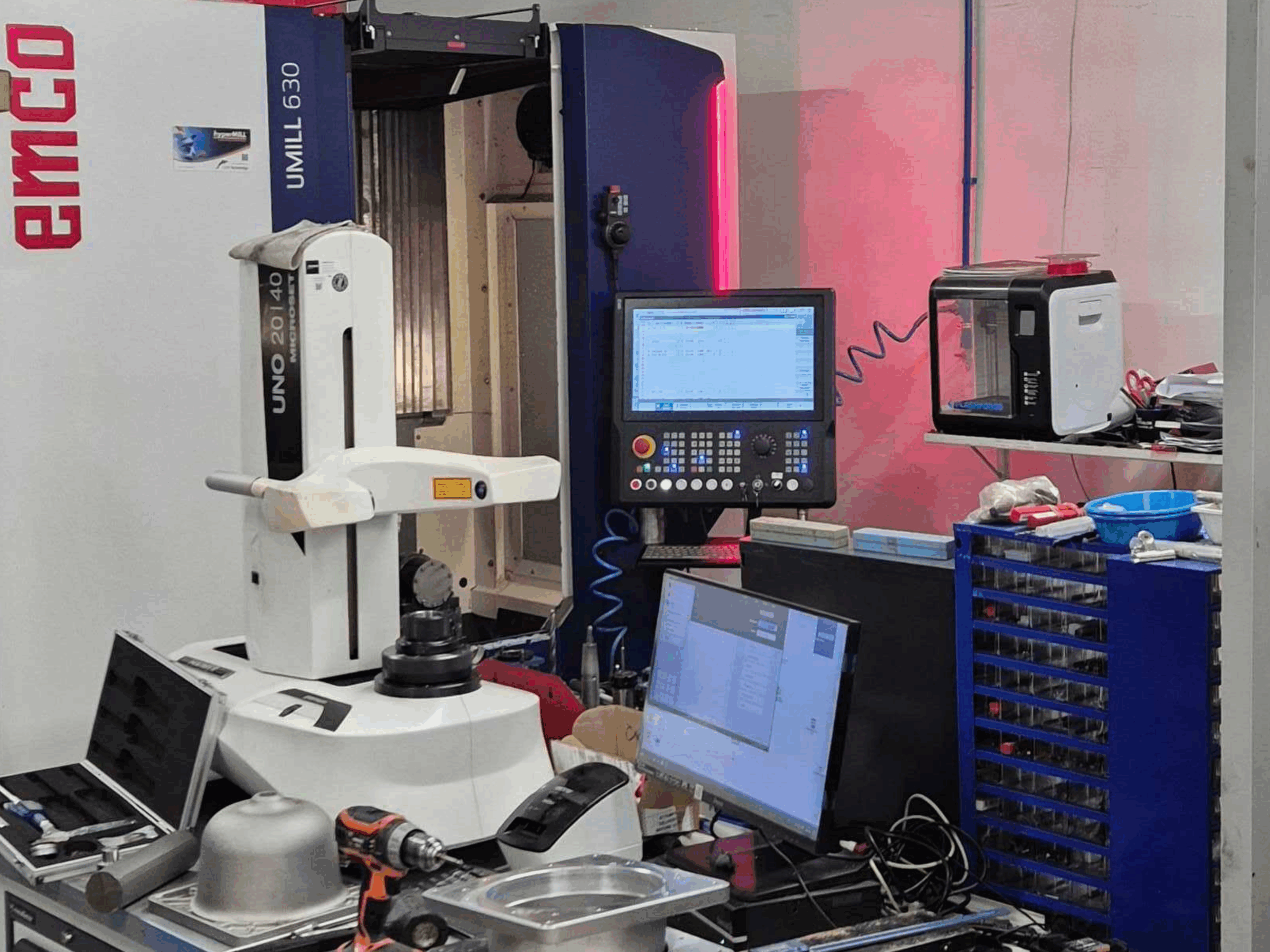

Millpol is a modern CNC machine shop, based in Łódź, Poland, currently employing eight people. The company specializes both in milling and turning, offering a full range of services – from 3-, 4-, and 5-axis milling to turning on machines equipped with Y-axis, driven tools, and sub-spindles.

Millpol serves customers from various industries, handling both serial production and complex one-off projects. As CEO Kamil Słobiński explains: “We don’t focus on one specific industry – we diversify our orders and take on ambitious projects. We have a great team that thrives on challenges.”

Pictures: Millpol

Challenges before introducing Spanflug MAKE

Before the introduction of Spanflug MAKE, Millpol worked with Excel and Trello for quote preparation. Formulas were copied, and manufacturing times were recorded manually. The biggest problems were inaccurate quotes – either too low or too high – and the time-consuming process of manual calculations, especially for custom-made products. The team also had to simulate the entire production process manually. “With six to ten changeovers per day and a high variety of parts, we create a lot of quotes. The conventional method was time-consuming and imprecise,” says Słobiński.

Implementing Spanflug MAKE

The company first discovered Spanflug MAKE. Shortly after implementation, they began seeing clear benefits. “The biggest advantage is the speed of quoting and the ability to fine-tune parameters, so that actual production times align with the calculations. Thanks to previously collected manufacturing data, this adjustment was quick and easy.”

The software proved to be intuitive and fast, making it easy for new users to get started without extensive training. This intuitive design reduces onboarding time and minimizes errors, which means we can generate accurate quotes faster and with more confidence for our customers. In combination with real-world production data, it enables highly precise and reliable cost calculations – a critical advantage in today’s fast-paced manufacturing environment.

Real case

In the past, I would have said no – the logistics of such a project were overwhelming for a small company. But with Spanflug MAKE, we prepared the quote in no time, the customer placed the order, and I had a complete list of materials and stock ready to go.

Benefits of using Spanflug MAKE

Saving time and the possibility to delegate quoting

The benefits turned out to be broader than initially expected. At first, the biggest value seemed to be time savings. Today, the company emphasizes another key benefit – the ability to delegate the quoting process. “In just a few days, we can train someone without a manufacturing background to handle quoting tasks independently. That frees up my time for Gemba walks, that is, spending time on the shop floor to observe processes, support the team, and drive continuous improvement. Before, I was stuck behind a screen reviewing technical drawings, completely burned out.” Additionally, the data generated by the software helps the machining technicians and production planners choose the right methods and plan manufacturing within the targeted time frames.

Collaboration and support

Collaboration with the Spanflug team has been very positive. “Everything is working great. The tool definitely meets our expectations.”

Recommendation for other companies

“If you know your actual production times, Spanflug MAKE can become a powerful tool after configuration.”

With Spanflug MAKE, Millpol has moved from time-consuming, imprecise calculations to an automated and scalable quoting system. The solution enables them to handle even highly complex projects without expanding their team or investing in additional infrastructure.

Start for free. Benefit immediately.

Your machine shop, too, can benefit from automated quoting. Our software solution Spanflug MAKE is ready to use immediately and delivers precise results. No large database or long training phases are needed. And best of all: you can calculate up to 5 parts per month for free.