Automated quoting for CNC machine shops

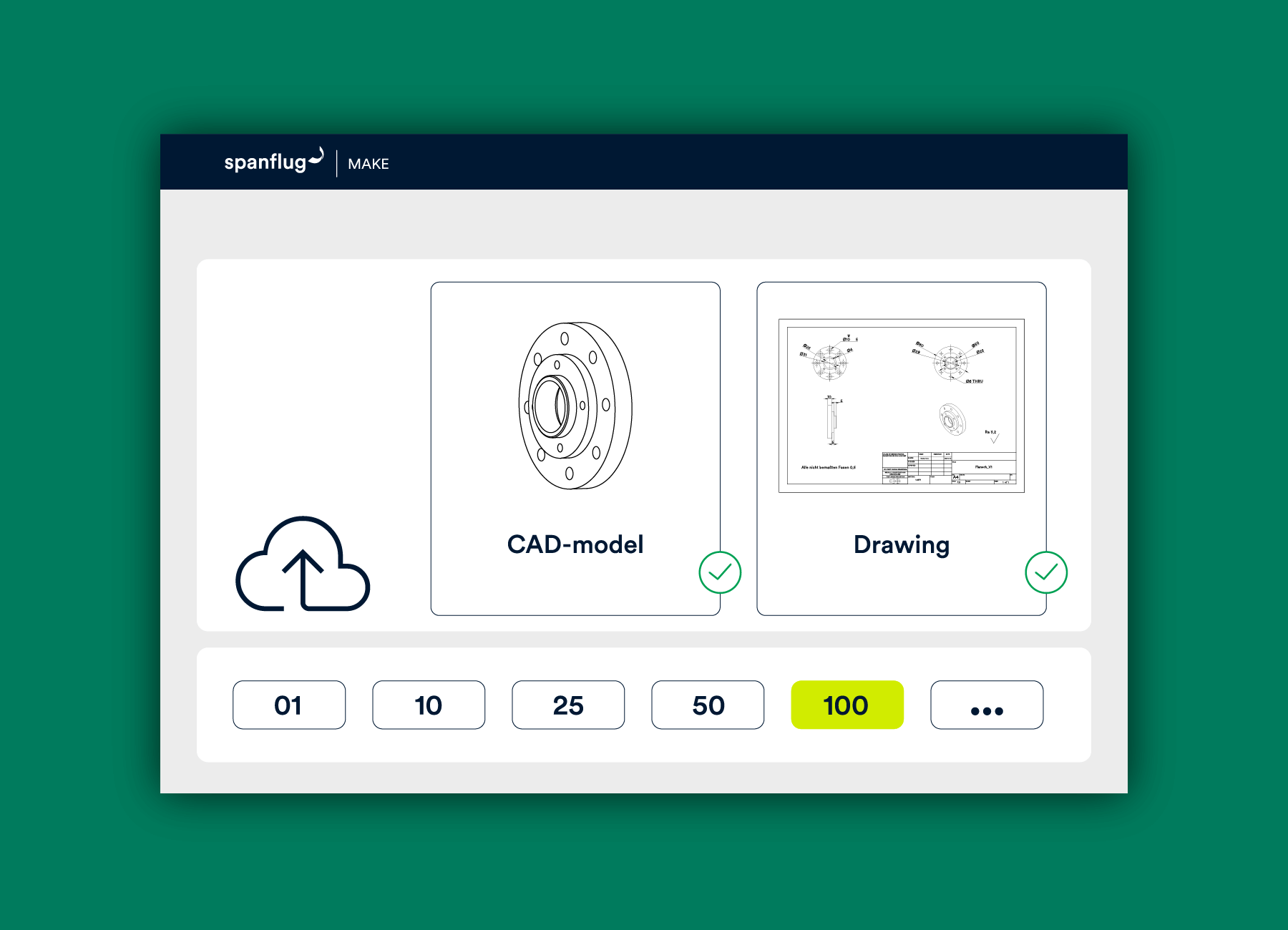

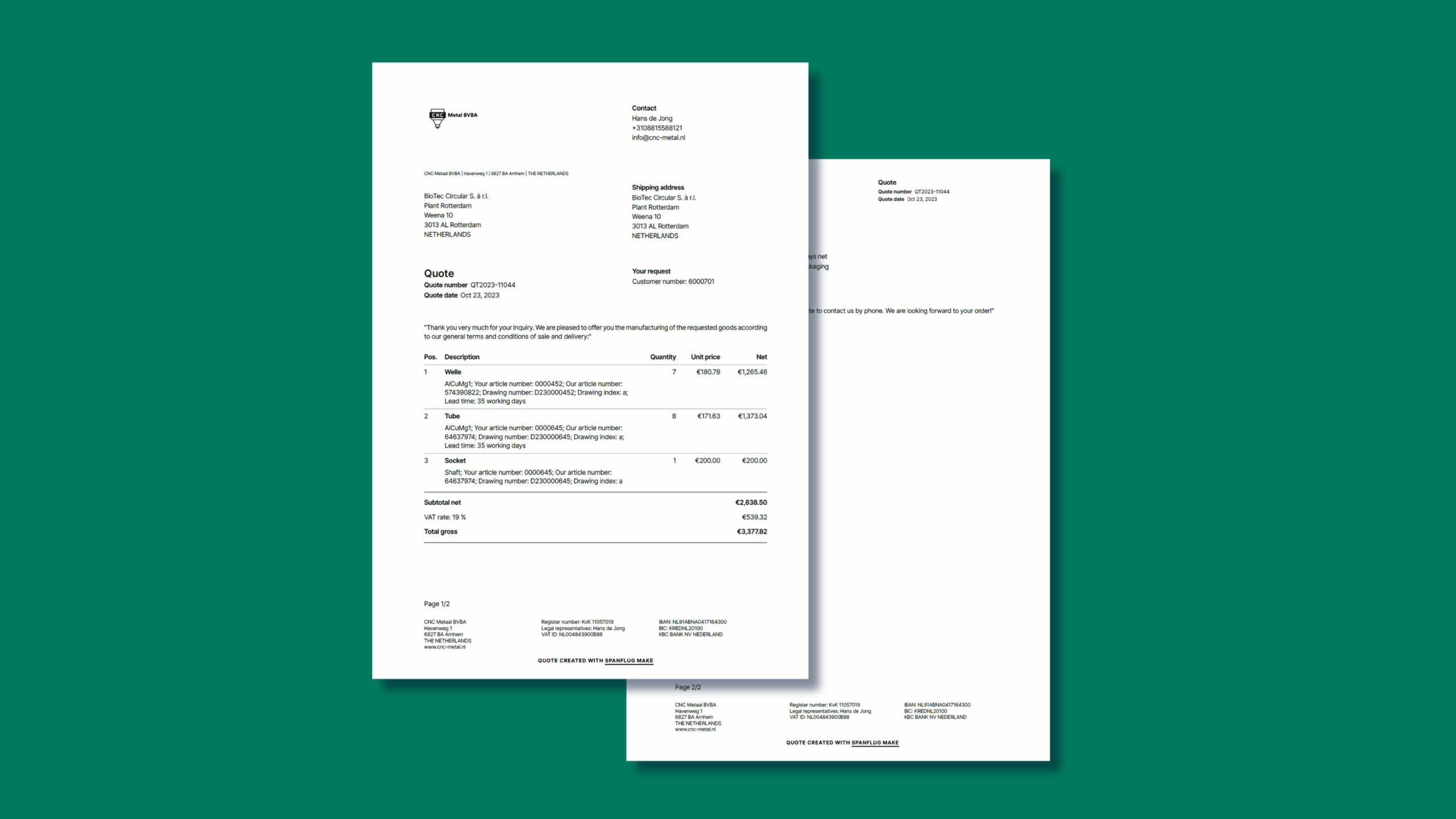

As a CNC machine shop, you can use Spanflug MAKE to calculate manufacturing times and costs for turning parts and milling parts based on CAD models and 2D drawings. The software automatically evaluates all features relevant to machining. You will get a detailed quoting proposal within a few seconds and can generate your quote with just a few clicks.

Easily calculate turning and milling parts with Spanflug

Save time. Reduce costs. Minimize risks.

This is how you benefit from our intelligent part analysis and the automated calculation of times and costs for your quotes.

Reduce effort and costs for quoting by up to 90%

Reply faster to customer inquiries thanks to automated processes

Reduce economic risks with reproducible, data-driven calculation

Start immediately, without database and long training phase

What users say about our quoting software

Optimize quoting for your machining company

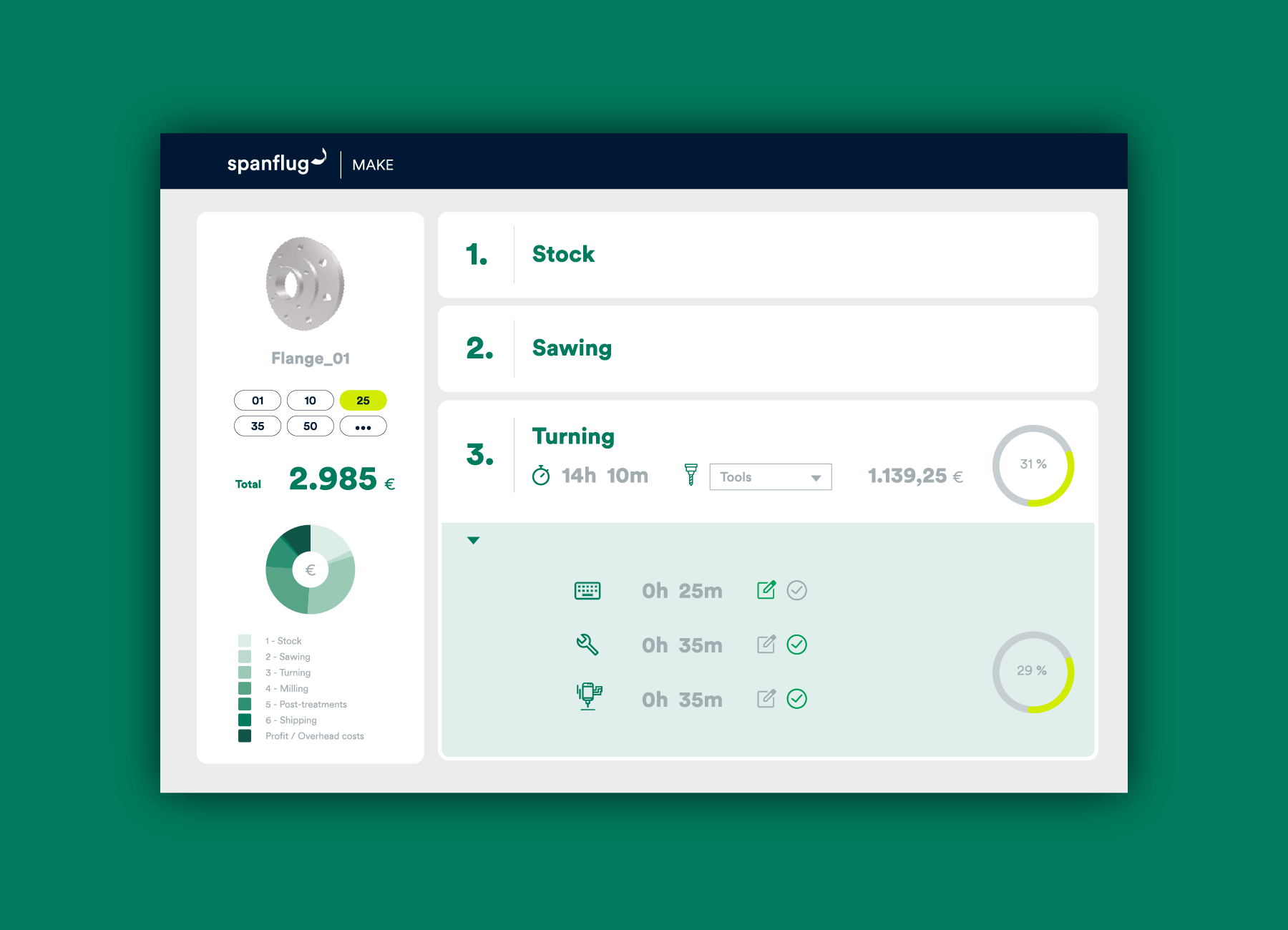

Spanflug MAKE calculates with preset parameters and delivers reproducible manufacturing times and manufacturing costs for your turning and milling parts in just a few seconds.

In order to achieve optimum calculation results for your machining company, you can create your own turning, milling and grinding machines. In addition to the machine tools, you can easily customize the calculation settings for your company, for example:

- Machine hourly rates

- Cutting values

- Material costs

- Set-up costs

- Programming times

- Margins and overheads

Manufacturing processes in our calculation

The automatic calculation in our quoting software Spanflug MAKE covers a comprehensive technical spectrum in the field of turning, milling and grinding, as well as a number of post-treatments. The manufacturing know-how for the following processes is stored in the software as standard and can be used immediately without further configuration.

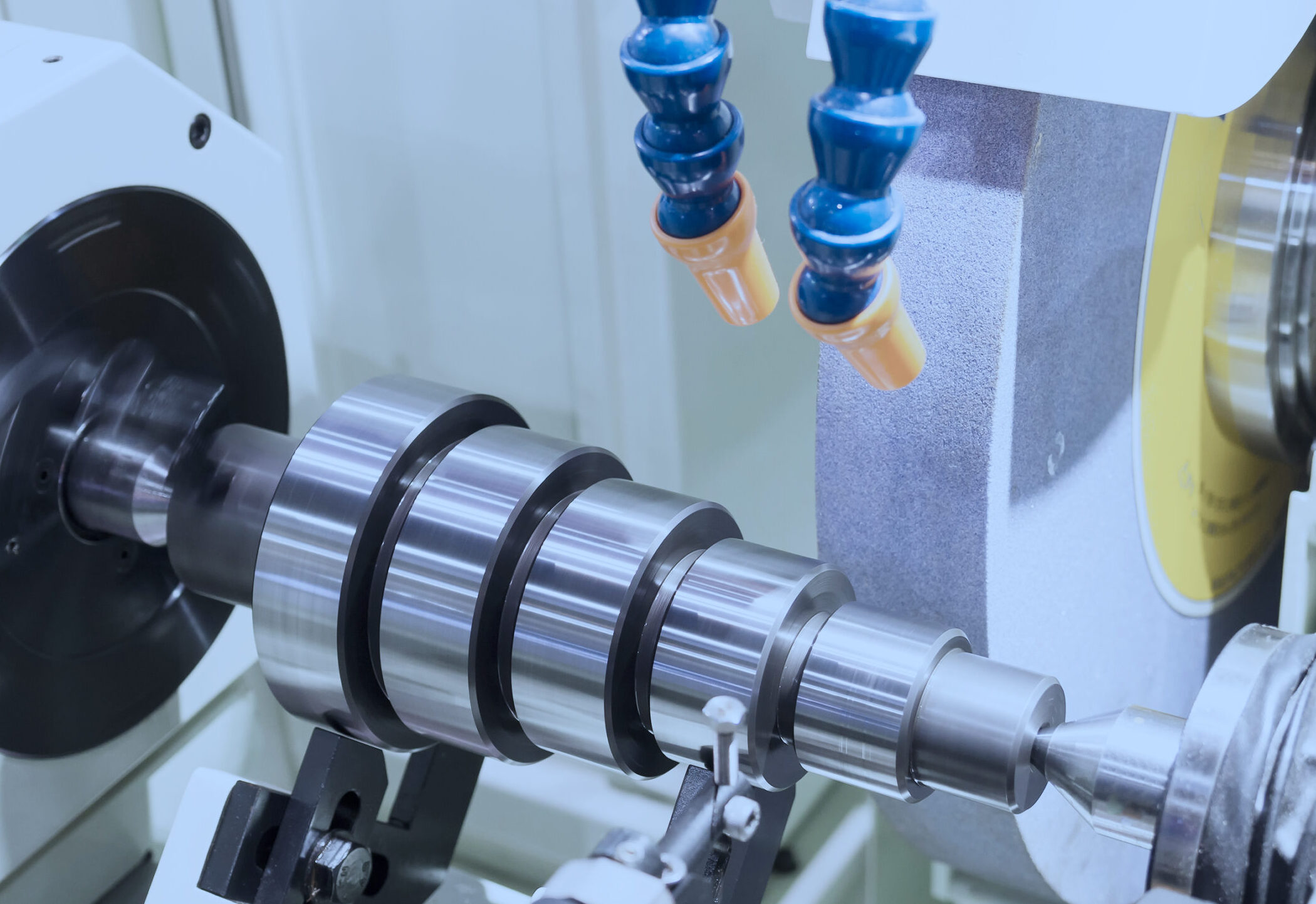

Turning

Turning parts up to a diameter of 1,000 mm and a length of 6,000 mm

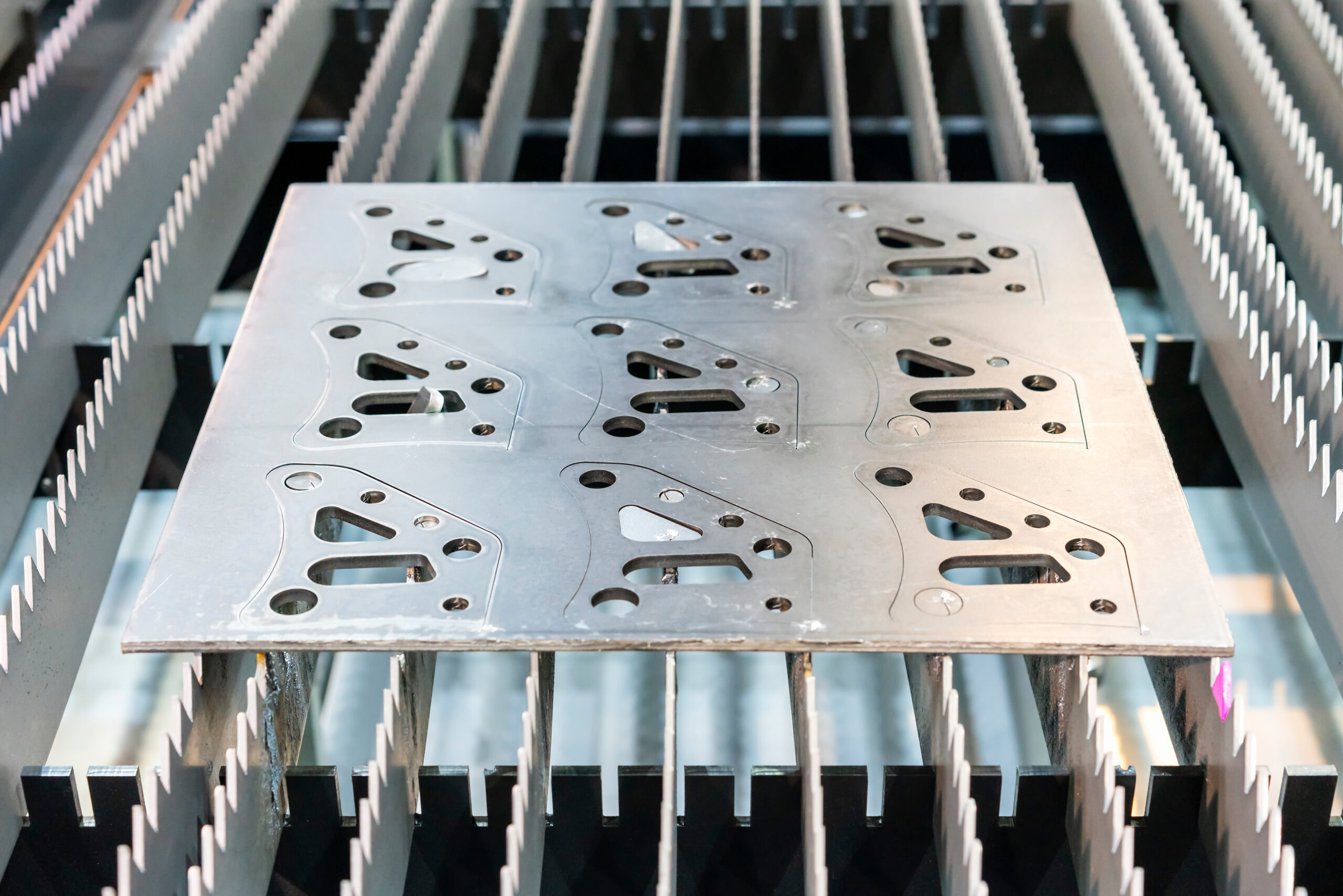

Milling

Milling parts up to 6,000 mm x 2,000 mm x 350 mm

Grinding

External cylindrical and surface grinding

Flexible selection of semi-finished products for costing

Standard stocks

Our database includes stocks from more than 60 materials, which are taken into account in the calculation. Spanflug MAKE uses daily updated prices from connected stock suppliers. This allows you to calculate precise costs in line with the market, saves you time-consuming inquiries to stock suppliers before you can finalize your quote, and helps you to hit the calculated margins even when material prices fluctuate.

Near-net-shape stocks

You can select near-net-shape stocks such as cast parts, laser parts or 3D printed parts as stock shapes and take them into account in the calculation. In this way, Spanflug MAKE supports economical and resource-saving manufacturing.

Contour cuts

You can select contour cuts such as laser, flame or water jet cuts as semi-finished product shapes and take them into account in the calculation.

Calculate post-treatments at the same time

Automatically recognized. Individually customizable.

Spanflug MAKE automatically recognizes the necessary post-treatments for the calculated part during the part analysis. However, you can adjust the processes, processing times and costs for post-treatments at any time.

More than 30 post-treatments

More than 30 post-treatments are available for automated calculation in Spanflug MAKE. From powder coating to anodising – the software calculates the various heat and surface treatments as well as coatings at the same time and also outputs these in separate work steps in the operational plan.