Efficient parts procurement for microfilter technology

Weppler Filter GmbH reports on its Spanflug experience: “The procurement of manufactured parts does not have to be time-consuming.”

The company

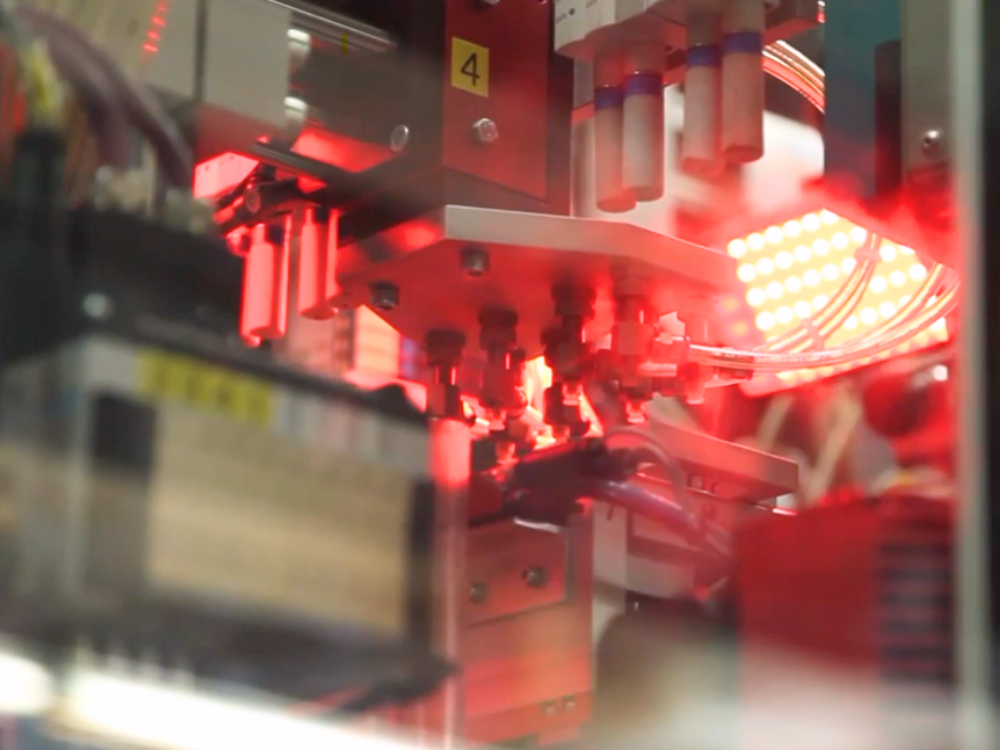

Weppler Filter GmbH is an international organization with tradition. The company was founded in 1935 and is one of the pioneers in precision and micro filter technology.

Weppler has fully automated its production. In order to enable this automation, high precision is required for any part used in their machines at the Weppler production sites. The materials and surface treatments for such individual parts are very diverse. “With Spanflug, we can get all custom parts from a single source, which takes a lot of pressure off us in terms of supplier management,” says Claudia Kloßner from the work preparation department.

Experience with Spanflug

“We have been sourcing from Spanflug for almost two years now and have now received well over 1,000 parts. It is the simple inquiry process that makes parts procurement with Spanflug so effective.”

Less effort compared to the conventional sourcing process

“The huge advantage is that you get prices and delivery times immediately and don’t have to wait for this information. You can complete the ordering process in one go.”

Online platform with personal customer advisor

I think it’s great that, at Spanflug, I not only have an online platform in front of me, but also a personal customer manager for all my technical and order-related queries. If the automated part analysis shows that a part is not machinable, there is always a competent CNC expert at Spanflug who can give me detailed information about why the part cannot be manufactured. This gives us the opportunity to redesign the part. I get this important information quickly and easily over the phone.

Launch your project with Spanflug today!

Sign up and get your instant quote.