Simplicity that convinces

Case study: Dürr Metall & Kunststofftechnik uses our quoting software to automatically calculate manufacturing times and costs.

The company

“What makes us different?” Michèl Dürr doesn’t have to think long. “We offer our customers high quality and can react very flexibly to very different jobs.” He has been running Dürr Metall & Kunststofftechnik in second generation, since 2019.

His customers include manufacturing companies from the electrical and microtechnology sectors as well as from the construction and medical industries. “With our CNC milling and turning machines, we manufacture parts from a wide range of materials such as stainless steel, copper, aluminum, plastic and even titanium,” says operation manager Daniel Schäfer, pointing to a milling machine in the production hall where nose implants made of this extremely strong light metal are currently being manufactured. “We supply not only parts, but also complete solutions. We are reliable and fast in everything we do,” he states proudly. Dürr was able to prove this reliability at the beginning of the pandemic, for example, when a customer started manufacturing respiratory masks. He needed a custom machine for welding the masks within a short period of time. “We milled a large number of titanium parts for this machine in a hush-hush operation,” says Michèl Dürr.

The company currently employs just under 20 people. If the managing director has his way, the team is set to grow further: “We want to grow, even if this has become somewhat difficult due to covid.” The CNC machine shop is planning to invest in a new machine tool in 2021. “Then the order intake will hopefully have recovered,” he says confidently.

The right partner at your side

The fact that Dürr Metall & Kunststofftechnik has been part of a network of qualified manufacturers from all over Germany for several months is also helping to improve the order situation. This network was set up by Spanflug Technologies, a start-up from the Technical University of Munich. With this network, Spanflug always provides its customers with the right partner – for example Dürr Metall & Kunststofftechnik from Karlsbad.

“In this supplier portal, the customer receives the parts at a fixed price,” explains Operations Manager Daniel Schäfer. “We noticed that the prices at Spanflug always fit perfectly, whereas they often inflated with us, especially with increasing order volumes.”

It was also not possible to determine the price quotes in a reproducible manner because certain parameters such as set-up or manufacturing times had to be estimated and were therefore highly dependent on empirical values. For some time, Managing Director Dürr and Operations Manager Schäfer had been looking for a more efficient solution that would speed up the calculation process, especially for complex turning and milling parts, in order to increase the accuracy of their quotes. Then they got talking to the experts at Spanflug.

Reliable quoting software

The Munich-based company offers companies such as Dürr Metall & Kunststofftechnik Spanflug MAKE for precisely these cases. The quoting software is based on a pricing algorithm that Spanflug has been using for its online platform for the procurement of CNC turning and milling parts since 2018. This algorithm has been optimized on the basis of more than 1,000,000 turning and milling parts. Features relevant for manufacturing are automatically extracted from a CAD model – and optionally from a technical drawing. In addition, the manufacturers can see a detailed breakdown of the calculated costs for material, set-up, programming, manufacturing and shipping, and adjust them individually.

“We were able to test the full version free of charge,” reports Schäfer. It was intuitive to use, so there was no need for extensive training – an online seminar was sufficient for the introduction. Both Managing Director Dürr and Operations Manager Schäfer were quickly convinced by the benefits, such as the simplicity and time savings in quote preparation. Together they decided to have the software activated for the company after the test phase. Less than an hour later, it was up and running. This is because Spanflug MAKE is a cloud-based software-as-a-service solution that runs without installation or a database.

Reach your goal without much effort

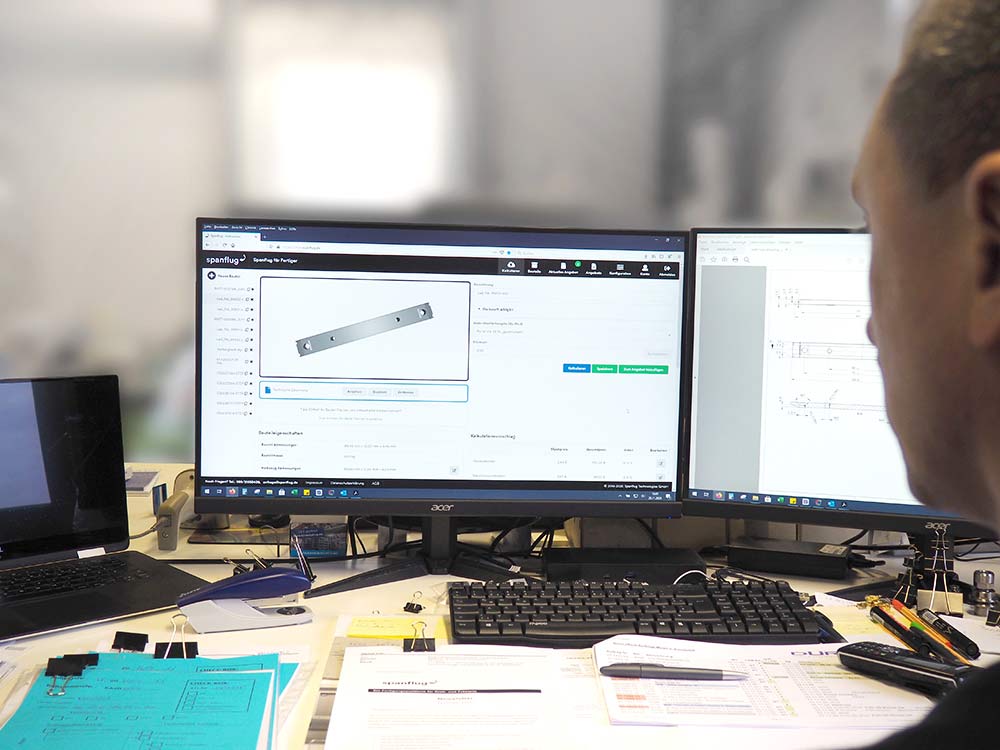

Daniel Schäfer uploads the CAD model and the technical drawing. The part appears on the screen in 3D view. The software automatically reads in the required information about the workpiece, such as surface condition, material and tolerances. The program detects whether there is a thread, for example, or sharp corners and edges, which are often not visible on the drawing, especially with complex parts. “It also recognizes whether the parts can be manufactured on the machine at all,” says Schäfer. “If not, the program will issue a warning.” This is an important aid for the operations manager, who does not have to think his way into the process first.

The software accepts the information “aluminum” as a material and automatically hides all other available materials. It also handles other parameters in the same way. Miscalculations can therefore be ruled out right from the start. As the part to be manufactured is a milling part, there are no lathes to choose from. The operations manager clicks through the various fields. He can variably change all important parameters. For example, he has stored details of the machine tools used, such as type, speed or size, and customized calculation settings such as margin, setup and material costs. He estimates that it takes just under two hours to program the part on the CNC machine and around twelve minutes to manufacture it. “I can adjust these values at any time,” explains Schäfer.

The set-up times seem too short to him, so he extends them by a few minutes. The program asks him whether a measurement report or a material acceptance test certificate is required. Schäfer then selects the quantity required by the customer. After a few minutes and a few clicks, the selling price appears on the screen: with five parts, each part costs 147 euros.

“It is important that we can freely set the values within a certain range,” says the operations manager. “We know from our own experience how long our colleagues need for set-up, for example.” Spanflug MAKE recalculates the price after each change. Optimized settings are particularly necessary for demanding parts, for example if they have extremely thin walls – the material must not give way at these points during processing.

This also applies to changes in material prices. “If we get the aluminum at a lower price, we indicate this in the software for this order, which has a positive effect on the price quote,” says Schäfer. “We may also be able to save on tool paths during manufacturing, which is particularly noticeable with higher quantities. If the number of items changes, the user simply has to type in the new value. The software adjusts the price – and shows the graduated price for 10, 25 or 150 parts, for example.

Experience Spanflug MAKE

One of our experts will be happy to give you a personal demo of our quoting software and answer any questions you may have. For a quick introduction to our solution, watch our free live or on-demand webinars.