Laser cutting – fast and reliable

Spanflug is your partner in laser cutting contract manufacturing. We manufacture your laser parts quickly and reliably with ISO 9001:2015 certified partners.

What is laser cutting?

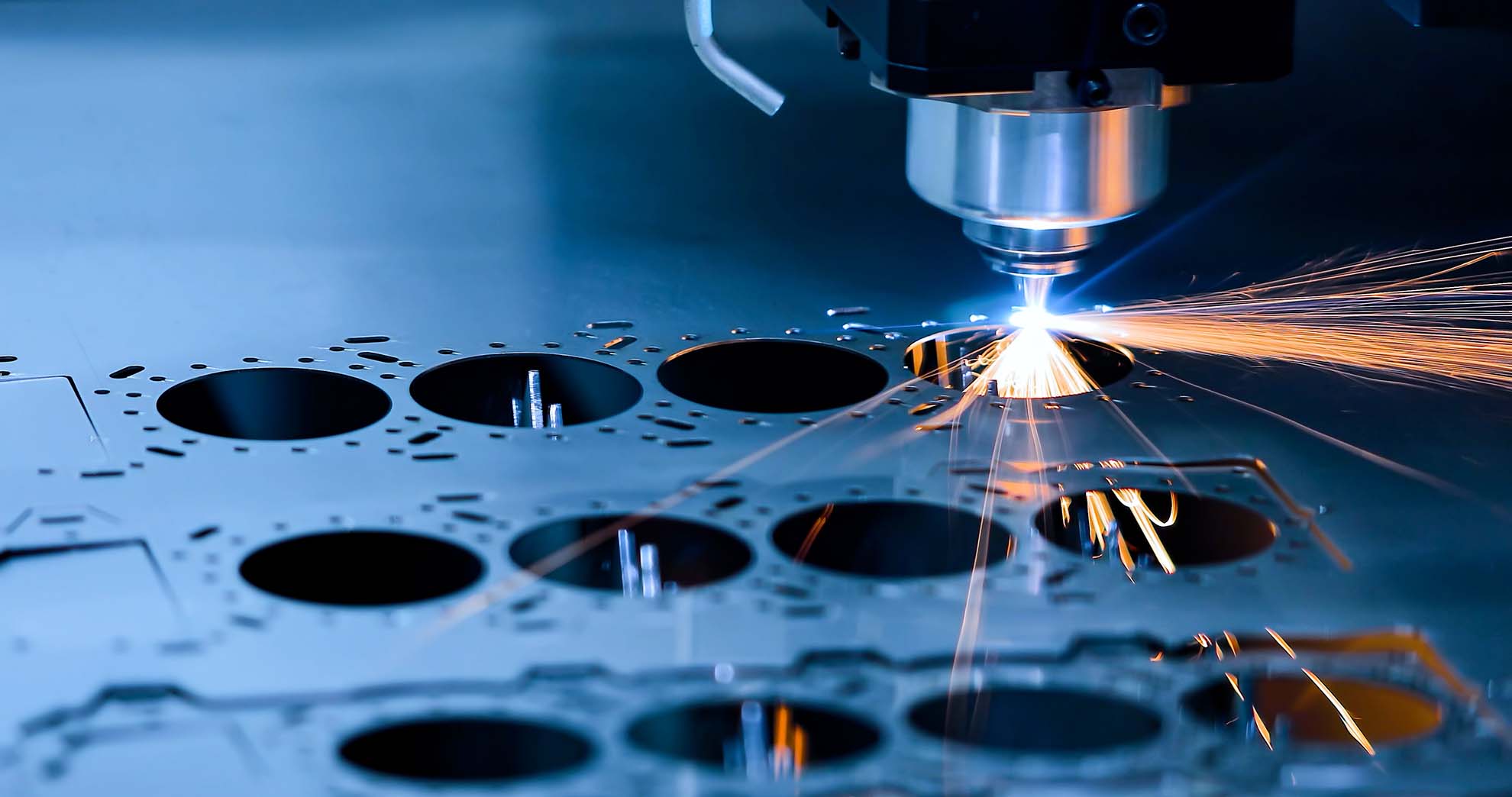

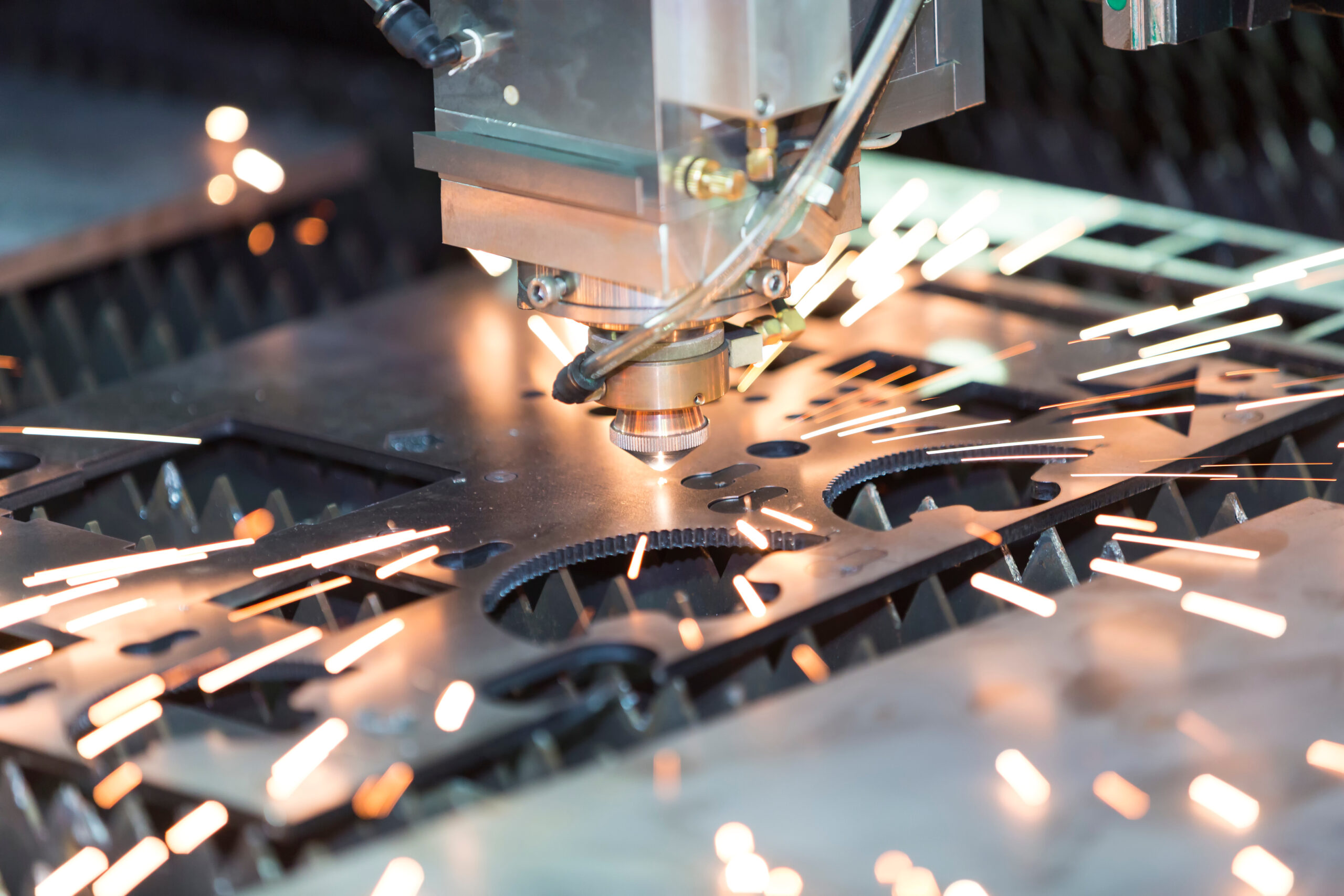

Laser cutting is a thermal cutting process in which a focused laser beam cuts materials such as steel, stainless steel or aluminum along precise contours. Sheets and tubes up to a wall thickness of around 20 mm can be cut. In contrast to machining processes such as milling or turning, laser cutting is contactless and does not exert any mechanical forces on the part. This means that no clamping devices are required for the stocks the machines can cost-effectively machine very large and numerous parts. Complex and intricate two-dimensional contours can be produced with high repeat accuracy. The achievable tolerances and surfaces of the cut edges depend on the sheet thickness and are described in ISO 9013.

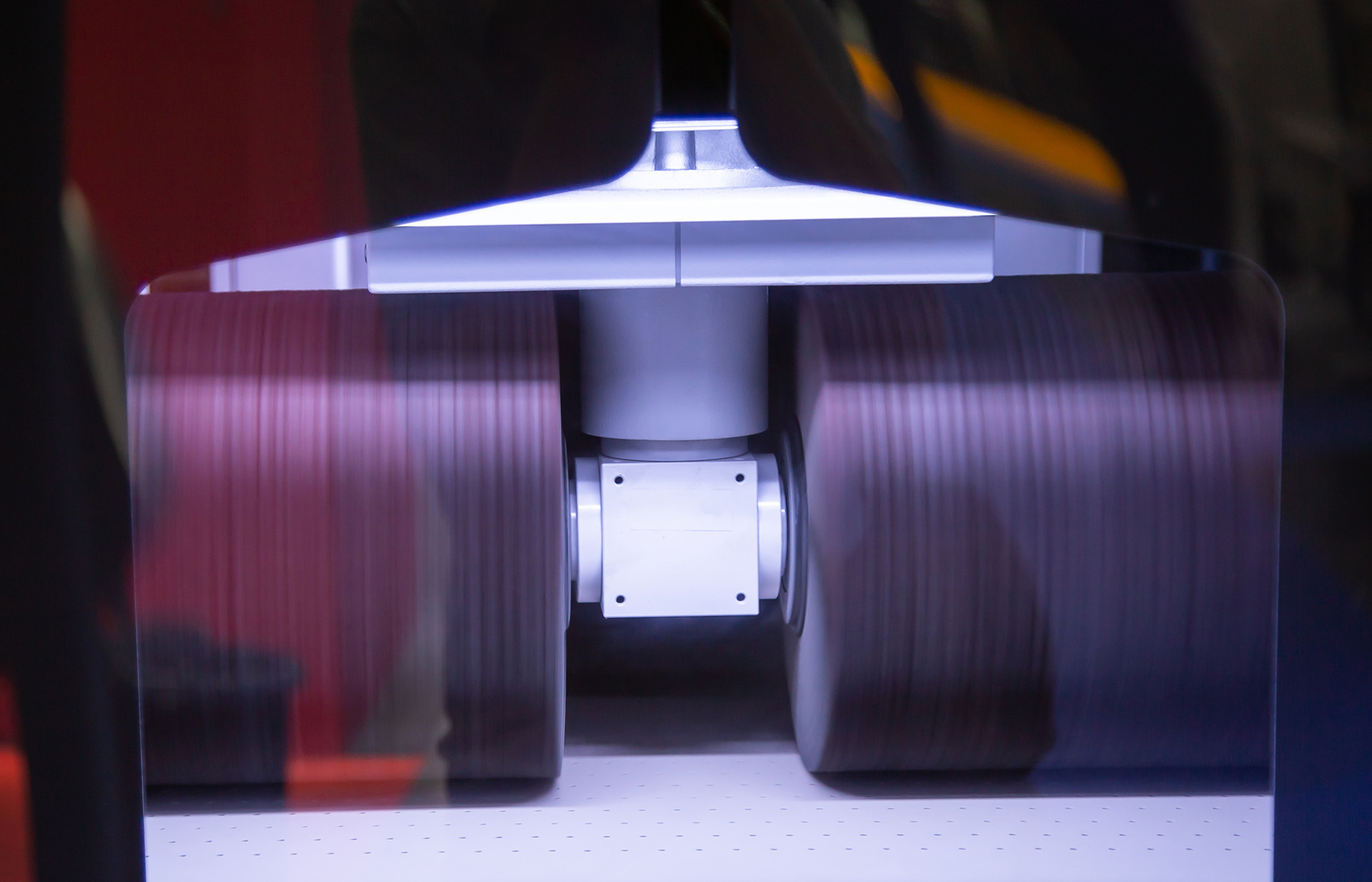

How does laser cutting work?

To cut the material, a laser heats the material with pinpoint accuracy until it melts or vaporizes. Supported by a cutting gas – usually nitrogen – the liquid material is removed from the kerf. The laser cutting system is controlled by a computer (CNC = Computerized Numerical Control). The cutting movements and cutting geometries are defined by an NC program, which is usually generated from a CAD model (CAD = Computer Aided Design, e.g. in .step or .dxf format) using programming software (CAM = Computer Aided Manufacturing). While CAM software calculates complex tool paths for turning and milling parts and optimizes parameters such as feed rate, speed and tool selection, it focuses on efficient cutting paths and optimal material utilization for laser cutting. As the cutting contour is usually generated with a two-dimensional movement, the process of creating the program can be automated very easily and also supports the cost-effectiveness of this manufacturing process.

Benefits of laser cutting

- Non-contact and therefore force-free separation process

- High precision for complex contours and thin sheets

- Low post-processing effort

- High cost-effectiveness for individual items and series production

Procure laser parts quickly and easily with Spanflug

The procurement of laser parts can be complex and time-consuming – from making inquiries with several contract manufacturers to obtaining quotations and processing orders. With Spanflug BUY, you can do this in just a few clicks.

Which laser parts can you have manufactured by Spanflug?

We manufacture your laser parts quickly and reliably from 5 working days. We deliver:

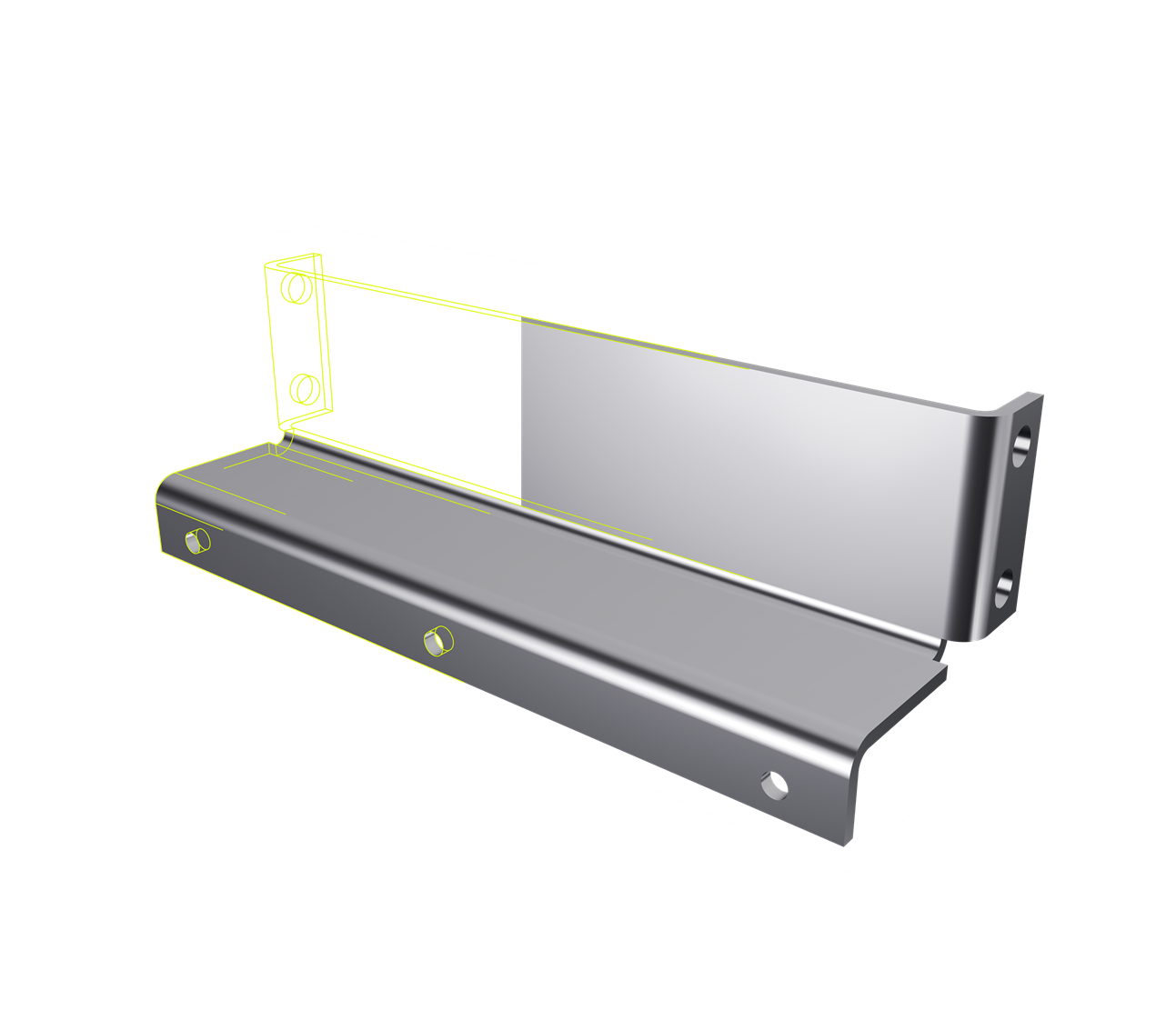

- Laser parts as well as bending and folding parts

- Prototypes and individual parts

- Small series

- Serial parts

- Over 16 materials can be ordered online

Are you looking for a contract manufacturer in the field of laser cutting?

Contract manufacturer laser cutting: Why is digital procurement worthwhile?

Contract manufacturing in laser cutting means that companies outsource the manufacturing of laser parts to specialized suppliers in order to save costs and resources. However, the challenge often lies in selecting the right, appropriately specialized partner, quote preparation and coordination of order processing.

Spanflug eliminates this effort:

- No time-consuming supplier screening – we will find the optimal manufacturing partners for you.

- Reliable quality assurance – all parts meet the highest standards.

- Instant quote online in just a few seconds

- Easy ordering & fast delivery in as little as 5 working days