More time for precision thanks to lean, digital processes

Case study: As a partner in the Spanflug network, CNC machine shop Grabacz gets orders without own sales effort and increases turnover and efficiency.

About the company

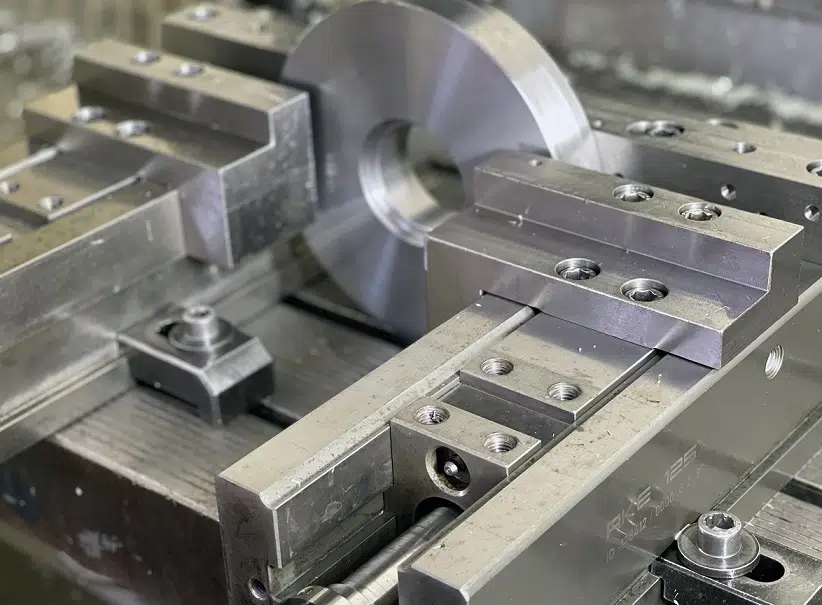

Manufacturing special parts with often tight tolerances – this is exactly what characterizes Grabacz GmbH & Co. KG in Greven in the district of Steinfurt in North Rhine-Westphalia, Germany. The CNC machine shop is part of a network set up by the Munich-based technology company Spanflug. The most important advantage: Grabacz can accept suitable manufacturing jobs directly on the platform and start machining without having to prepare a quote or spend time and effort on customer aquisition. This saves administrative effort and makes processes significantly more efficient.

“We specialize in precise contract manufacturing of turning and milling, eroding and grinding,” says Michael Grabacz, describing his company. He is the commercial director of Grabacz GmbH & Co KG and runs the family business together with his father. Grabacz Senior founded the company in 2003. The manufacturer mainly machines parts from stainless steel, but also tool steel, aluminum and plastic. “The dimensions of the parts that we manufacture come usually with very tight tolerances. We like to work a little more precisely and neater than our competitors,” says the managing director.

The challenge

Focus on precision

Pressure on prices and deadlines

“We offer our machining services at competitive prices, and we are fast and flexible,” explains managing director Michael Grabacz. However, there are always competitors in the market who would push the price down. Some of the regular customers also turn to these competitors from time to time – but will come back to Grabacz for quality reasons at the latest for the next job.

Stronger through distributed manufacturing in the network

It must have been three years ago when Michael Grabacz became aware of Spanflug Technologies through internet search. The technology company – founded in 2018 as a start-up of the Technical University of Munich (TUM) – runs a network of qualified manufacturers.

On its manufacturing platform, customers benefit from a fully automated ordering process for CNC turning and milling parts. Based on the CAD model and a technical drawing, users can order parts online immediately without spending days waiting for supplier feedback to RFQs. This allows their companies to reduce process costs for procurement significantly. The ordering process is often shortened from days to just a few minutes. Spanflug uses its network to match ordered parts with the most suitable partner, such as Grabacz GmbH & Co KG.

Grabacz quickly recognized the potential to streamline and digitalize processes in order procurement and quoting and applied to become a manufacturing partner for the Spanflug network.

“We offer a wide technical range, a fast response time, and can supply parts in the desired quality. We also have good contacts with material suppliers,” reports Grabacz. “With these characteristics, we fulfill important requirements that Spanflug has for its manufacturing partners and we are certainly a good match.”

Getting jobs without own sales efforts

With Spanflug, manufacturing partners receive orders through the platform without having to write quotes and do customer acquisition. “This means we no longer have to calculate and negotiate with each individual customer. This saves us a lot of time and is easy on the nerves,” says Grabacz happily. However, not only the order price is fix, but also the delivery times. This significantly reduces the administrative efforts.

The manufacturer only has to decide whether he accepts the order or not – and he can make this decision much more quickly. Manufacturers, such as Grabacz GmbH & Co KG, receive pre-selected orders based on their machine parks, technical range and machine capacities. “It is almost never the case that we have to bend over backwards for a job we receive through Spanflug or for which we have to involve third party partners of ours. It’s a real ‘match’ with our capabilities,” confirms Grabacz.

Another major advantage: The customer provides all 3D models and drawings via the platform – this is the basis for the high precision of the prices calculated by Spanflug and the allocation of orders.

As an interesting side effect, Grabacz praises the fact that Spanflug allows him to focus more on its core competence – machining: “Spanflug basically works for us as a digital sales colleague. Free of charge, because these orders are sent to our e-mail inbox virtually automatically.”

If a job is particularly urgent, a Spanflug operations manager will call in directly. In such time-critical cases, the CNC manufacturer is paid an express surcharge. “We can view all the details in the supplier portal and accept the order immediately or reject it by providing feedback,” says Grabacz. “We can play to our strengths, especially when things have to be machined and delivered fast. Thanks to our good contacts with stock suppliers, we can get the stocks we need quickly.”

The machine shop makes good use of the time until the stocks arrive: employees program the machine and do work preparation. “In the best case scenario, we can even beat the delivery date,” describes Grabacz. Every Spanflug customer who urgently needs the part or the small series will be grateful for every day that the delivery arrives earlier. This way, all three parties benefit.

Conclusion

Thinking outside the box

“The network gives us the opportunity to think outside the box and accept orders that are quite different from those requested from our regular customer base,” says Grabacz. He feels closer to the market, knows what is needed and how to develop and grow his business, especially in terms of what machines will be needed in the future. Michael Grabacz is convinced that this will enable him to react faster than many of his competitors in the market and be well prepared for the future. Spanflug has thus become a reliable source of revenue for the manufacturer in recent years.

“It is always exciting to machine even challenging parts and a welcome change from the parts of the regular customer base,” Grabacz is pleased to say. “With our own high standards of quality and cost-efficiency in manufacturing, we spare no effort when it comes to product and customer satisfaction. This is another reason why we value the close exchange with Spanflug, and not just about the manufacturability of parts. Through our feedback as a partner from the very beginning, we were also able to contribute to further improving the functionality of the supplier portal and the precision of the price algorithm,” the managing director explains proudly.

Michael Grabacz and his company thus see themselves as supporters of the national mechanical engineering market and are contributing to make the industry stronger – with the support of Spanflug’s manufacturing network.