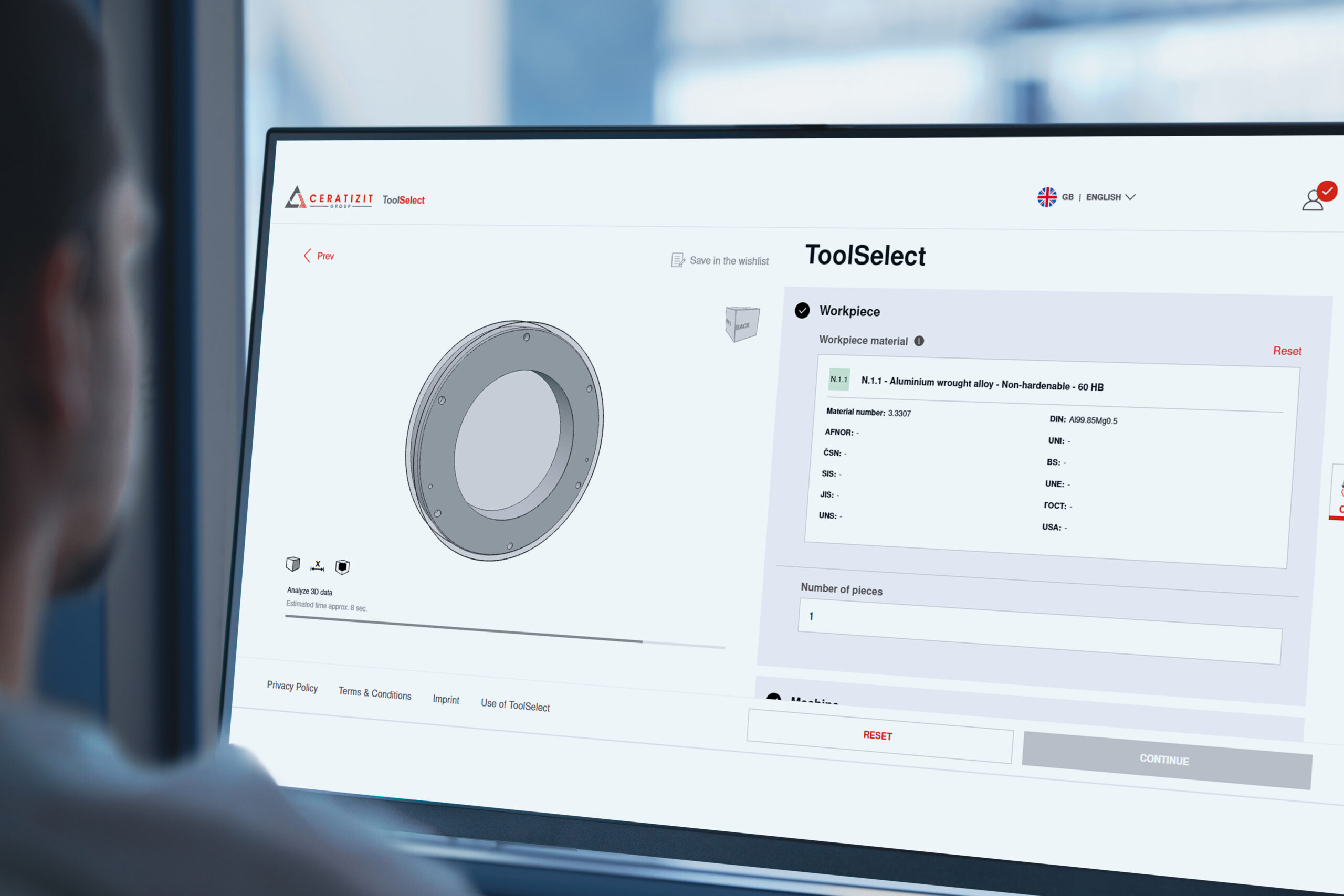

Spanflug powers 3D analysis in CERATIZIT’s new application ToolSelect

Our partner relies on Spanflug technology for the 3D analysis in its app ToolSelect, enabling fast digital tool selection for CNC machine shops.

Digital tool selection in just 90 seconds

When CERATIZIT unveiled its new digital tool selection application ToolSelect to visitors and the trade press during this year’s EMO in Hannover, we were very proud to be part of the launch – and to make a significant contribution to the technology behind the innovation.

Spanflug’s intelligent, AI-assisted algorithms are a key element of the 3D analysis in ToolSelect. Thanks to our proprietary technology, the app can automatically detect and interpret uploaded 3D models, identify all features relevant for machining, and provide the data foundation for generating a complete tooling solution, including inserts, holders, and cutting data.

With its 3D analysis powered by Spanflug, ToolSelect demonstrates how advanced automation can turn data into decisions – making digital tool selection possible in just 90 seconds. The app impressed the audience with its intuitive workflow and has the potential to become a real game changer not only for work preparation. The application goes beyond single operations. It considers the entire manufacturing process of a part and generates the most profitable machining strategy.

How machinists benefit

ToolSelect is a true business enabler for every manufacturer. Turning the 3D model into a complete tooling solution for the entire part is not about digitizing a catalog, it’s about introducing a completely new, disruptive way of finding the right tools. We’re proud that our technology powers the 3D analysis behind this innovation.

From guesswork to digital confidence

Digital confidence

For decades, machinists relied on experience, catalogues, and trial-and-error to find the right tools. ToolSelect provides standardized, data-driven recommendations that improve cycle time, part quality, and tool life. The integrated Spanflug technology ensures that the 3D model analysis automatically generates optimal machining strategies for the complete part, reducing setup time and eliminating mismatched configurations.

“Tool selection is becoming smarter, faster, and more reliable,” says Bianca Rief, Product Owner at CERATIZIT. “With ToolSelect, we’re giving users digital confidence – automated, transparent, and repeatable tool recommendations and a smart purchasing option that empowers machinists everywhere.”

Innovation through partnership

ToolSelect exemplifies how strong and multifaceted the partnership between CERATIZIT and Spanflug has become and how it continues to drive innovation. The close collaboration fuses deep tooling expertise and cutting-edge automation technology.

“We’re very excited about this new result of our close partnership with CERATIZIT,” continues Lucas Giering. “Together, we are shaping the future of digital tool selection and making the manufacturing industry stronger, smarter, and more competitive.”

A huge step forward for digital manufacturing

ToolSelect is more than a digital app – it supports both experienced engineers and newcomers in the machining industry, helping close the global skills gap while promoting efficiency and sustainability.

By combining Spanflug’s automation technology with CERATIZIT’s tooling know-how, ToolSelect sets new standards in terms of accessibility and precision for digital solutions in manufacturing.