Precise calculation, reliable supply chains, new distribution channels

Integration of data from SRS Stahl into Spanflug platform – how all sides benefit from the cooperation and the real-time data for steel stocks.

Real-time data for accurate price calculation

Since 2022, numerous stock suppliers have been directly connected to Spanflug’s digital manufacturing platform. Thanks to the technological integration, the price algorithm in Spanflug solutions can access prices and availability of stocks “in real time” and take these into account when calculating the most economical manufacturing solution. As a result, users benefit from an even more precise price calculation and greater reliability in the supply chain.

Minimize the risk of unexpected steel price fluctuations

SRS-Stahl GmbH has been among the first stock partners to be connected to the platform. In an interim report, the cooperation partners SRS-Stahl and Spanflug reflect on the expectations and results of the integration so far as well as the specific added value for users of the platform solutions.

As a leading supplier for metal processing, the Augsburg-based company permanently stocks around 1,400 tons of steel and non-ferrous metal in over 80 metal grades. In its own sawing, milling and grinding center, SRS-Stahl can also produce prefabricated steel bars and sawn plate blanks and thus implement individual customer requirements quickly and reliably.

Due to its high strength, good machinability and corrosion resistance, steel and stainless steel are indispensable materials for applications in the automotive, mechanical and plant engineering as well as the energy sectors.

This is also reflected on the Spanflug platform, where over 50% of all parts calculated in the past twelve months were based on stocks of steel grades. However, steel in particular is affected by the current fluctuating global market conditions and geopolitical events, both in terms of raw material prices as well as production capacities and therefore availability.

As the stock costs for turning and milling parts account for around 30 percent of the part value, the advantage of up-to-date data for precise price calculations is obvious. “Real-time data on our steel stocks enables Spanflug users to minimize the risk of unforeseen cost increases, making manufacturing processes more predictable and enhancing delivery reliability,” says Richard Stoll, Managing Partner of SRS-Stahl GmbH, summarizing the benefits of integration into the platform.

More efficiency for platform users

“By connecting daily updated stock data, we wanted to make the calculation of prices and delivery times for part in our solutions more reliable and also bring together the stakeholders along the value chain on our digital platform. This allows us to further accelerate the complex procurement process and make it more efficient, especially for the range of steel parts with their strong price fluctuations,” confirms Dr. Markus Westermeier, CEO and co-founder of Spanflug.

This is how users of Spanflug BUY and Spanflug MAKE software solutions benefit:

- Purchasers who are getting instant prices and are placing orders for their parts in Spanflug BUY benefit from an even more precise price calculation thanks to the up-to-date stock costs used by the Spanflug algorithm. The real-time availability of steel poducts at the SRS-Stahl warehouse also enables reliable delivery dates for their parts, optimizes planning for the purchasing companies and supports a reliable supply chain.

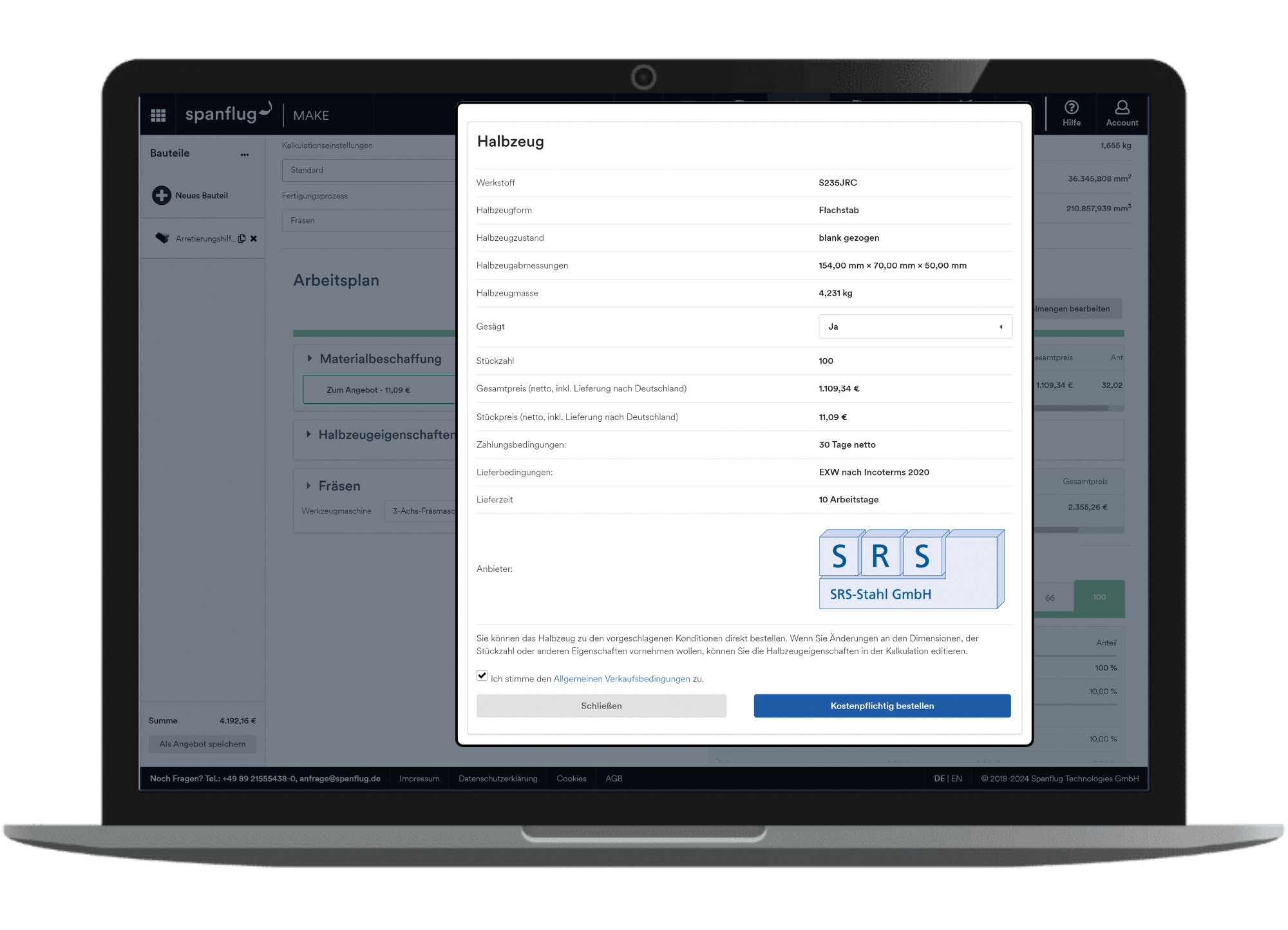

Manufacturers can order stocks from SRS-Stahl directly from the quoting proposal in Spanflug MAKE.

- Machining companies that use Spanflug MAKE The software solution suggests the most suitable stocks for the most economical production route. The most efficient machining process is always compared with the real-time data from SRS steel. The software also indicates which semi-finished product form and condition, e.g. a plate blank, is available from the steel supplier and at what price the manufacturing company can order this simply and efficiently via Spanflug. This means that the contract manufacturer no longer has to make inquiries to the material supplier and can obtain the plate blank at the exact price on which the calculation was based. This increases cost efficiency, minimizes the amount of work involved in procuring semi-finished products and provides greater security in order processing and margin expectations.

- Manufacturing partners in the Spanflug network can source steel stocks for orders, that they have received and accepted via Spanflug, easily and directly via the supplier portal. In this way, the manufacturing partners minimize their material procurement effort and can reliably process orders meeting the confirmed delivery date.

Joining forces for the future of digital manufacturing

In its own sawing, milling and grinding center, SRS-Stahl can produce prefabricated bars and rods or sawn plate blanks.

After two years in which the stock information from SRS-Stahl has been integrated into the platform, both companies have drawn a very positive conclusion: a real win-win situation for all user groups and also for the partners. Because the cooperation with Spanflug offers SRS-Stahl GmbH strategic advantages, enables new opportunities for digital sales and even optimizes warehousing, as Axel Schweihofer, Team Leader Sales at SRS-Stahl, reports:

“Working with Spanflug, helps us redefining our service offering. The platform allows us to reach many new customer segments that can benefit from our broad range of services – an ideal addition to our existing web store and our digital sales strategy. Here we can make full use of our strengths, such as our extensive product portfolio and fast throughput times in preparing custom stocks. In addition, the collaboration also promotes the integration of modern technologies into our own processes – such as in sales or warehousing – and thus strengthens our competitiveness and our brand image. Being closely interlinked with other innovative companies helps us to further develop our technological capabilities and drive forward our own digital transformation.”

Conclusion and outlook

By connecting SRS Stahl and a number of other metal and plastics suppliers to the manufacturing platform, Spanflug can offer real-time data for the entire range of over 60 materials for turning and milling parts.

“The collaboration provides an opportunity to leverage synergies between the two companies. This will lead to a mutual strengthening of the market positions and growth for both companies. Together, we have created the basis for new innovations and will jointly develop an extended range of products, which will benefit an even larger number of customers on both sides,” says Richard Stoll from SRS-Stahl. “We look forward to continuing to set new standards in the industry together with Spanflug and to driving digital manufacturing forward.”

The partners give a consistently positive summary of the added value that the collaboration has created so far. Image from left to right: Spanflug CEO Markus Westermeier and Product Manager Anita Böhm with Richard Stoll and Patrick Stoll from the management of SRS-Stahl GmbH.

Benefit from real-time data for stocks

Whether you are procuring custom machined parts via Spanflug BUY or are calculating manufacturing times and costs with Spanflug MAKE – you will benefit now from our technology cooperations with stock partners.