Intelligent algorithms powered by AI for more efficient machining strategies

News for CNC contract manufacturers at EMO 2025: Spanflug MAKE is evolving into a Machining Intelligence and helps machinists to solve a key challenge in small series production.

Spanflug at EMO 2025

Spanflug Technologies will showcase the latest advancements of their quoting software Spanflug MAKE during EMO 2025 at booth A47 in hall 6. The solution not only enables CNC machine shops to calculate manufacturing costs and times for turning and milling parts faster and create quotes more efficiently. With the new version, Spanflug MAKE is evolving towards a “Machining Intelligence”, that also supports work preparation and manufacturing strategy optimization. Thanks to AI-powered algorithms for part analysis, a high level of automation, and the integration of tool and stock data, software users can generate cost-efficient machining strategies with just a few clicks. This is especially valuable for small quantities and enables companies to manufacture more economically.

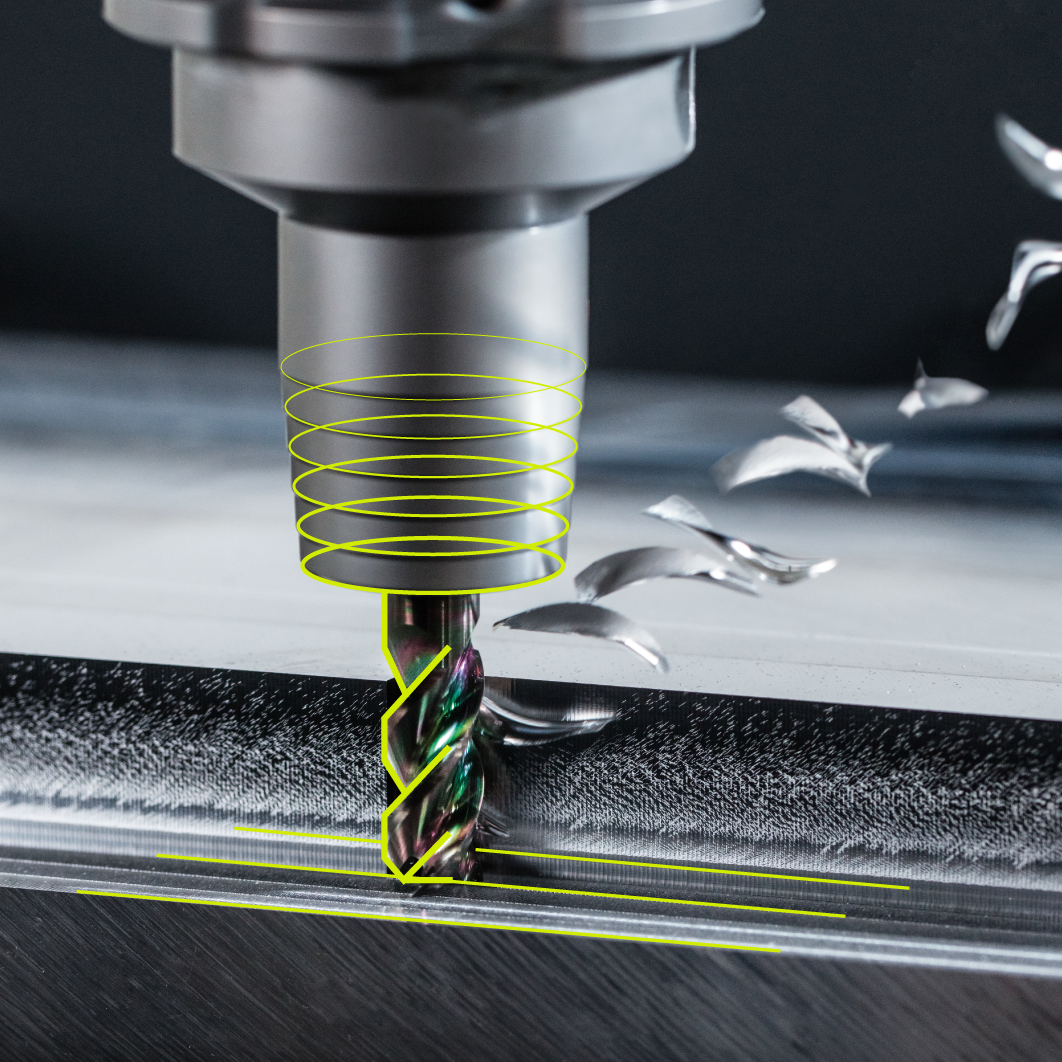

Image source: CERATIZIT / Spanflug

Main challenge in small-batch machining

CNC contract manufacturers who produce small and medium quantities often have limited time to determine the most economical machining strategy and optimize process parameters, unlike in large-scale production. Parts outside their current specialization typically pose significant challenges in quoting, work preparation, and manufacturing. Particularly with unfamiliar parts, companies often lack the experience needed for truly accurate calculations. Those looking to tap into new customer segments under rising cost and competitive pressure, and who wish to respond to customers faster with accurate quotes and manufacture parts profitably can reduce economic risks and complexity through Spanflug’s solution for intelligent machining strategies.

The AI-powered and data-driven path to optimal machining strategy

“This is exactly where our Machining Intelligence comes in,” explains Dr. Markus Westermeier, CEO at Spanflug. “We now support machine shops with more than quoting and work preparation – we help them become more efficient in actual manufacturing and find new, more economical ways to machine custom parts.”

The technical basis for this is the Spanflug algorithm, which is enhanced by artificial intelligence and trained on millions of parts. The software understands each part, analyzes the optimal manufacturing process, and generates an operational plan with the required stock materials, machine tools, cutting tools, as well as times and costs.

Modeling the manufacturing sequence with digital tool data

Increasingly integrating real-world data from throughout the entire manufacturing process into Spanflug’s software is crucial to the quality of the operational plans generated and accuracy of the calculations. In addition to stock data from connected material partners, Spanflug MAKE now also utilizes tool data. The strategic partnership with the tool manufacturer CERATIZIT plays a key role here and now brings concrete benefits for users. “The integration of CERATIZIT cutting tool data enables the software to model the manufacturing process and generate the most profitable machining strategy,” says Westermeier.

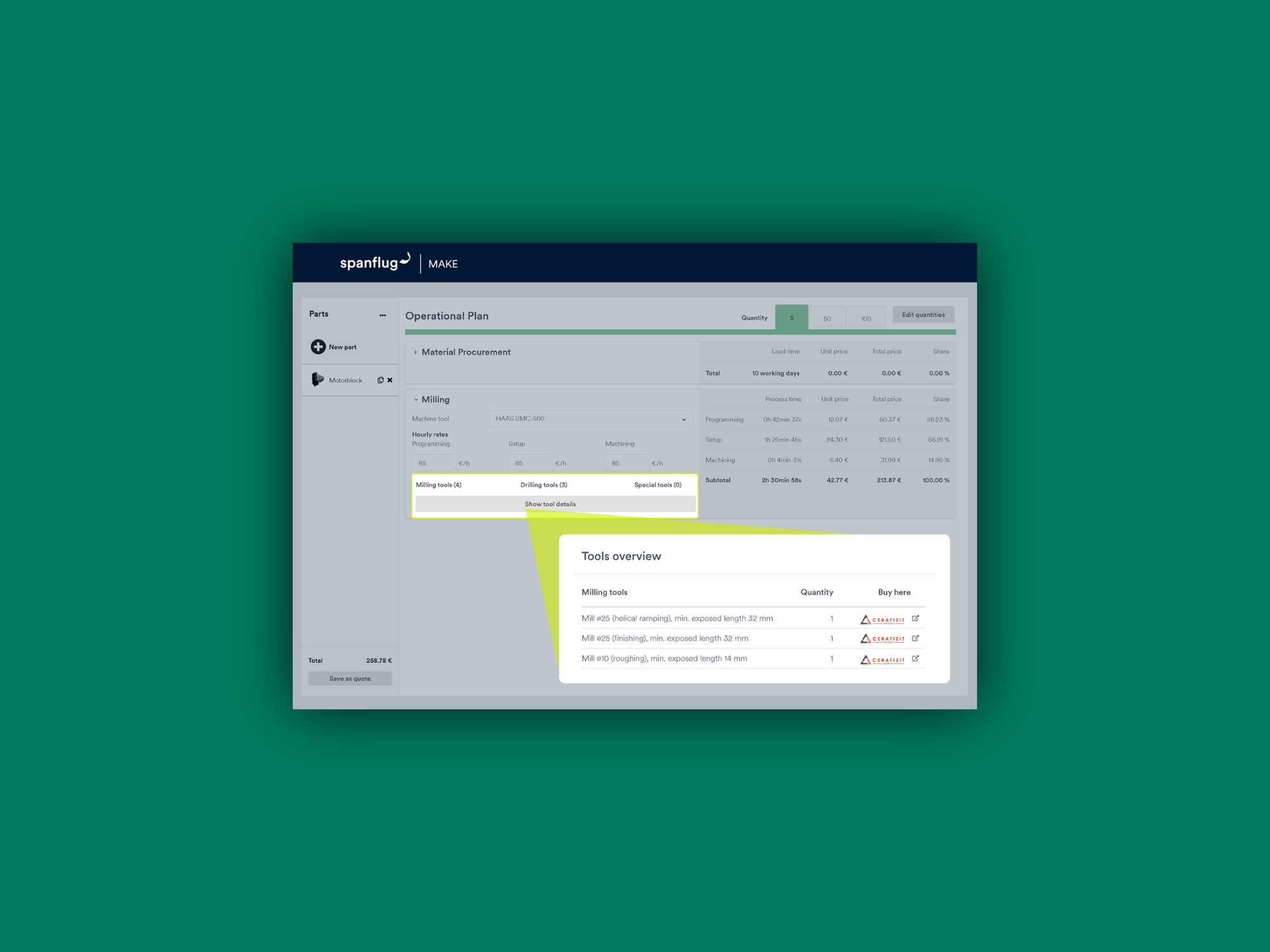

The latest version of Spanflug MAKE thus delivers not just a calculation proposal, but an operational plan with a recommendation for the most efficient manufacturing approach. This includes the following data:

Stocks

The solution integrates a comprehensive database with real-time prices and availability for a wide range of materials. The operational plan suggests the most suitable stock and incorporates it into the calculation. When needed, users can source stocks directly within the software without additional procurement efforts.

Machine tools

For each machining operation, the most suitable and economical machine is selected from the users’ own machine tools. By setting up their own machine tools with just a few clicks, users can easily customize the software, e.g. to set their individual machine hour rates and machine tool properties.

Cutting tools

In the latest version, the operational plan now also includes recommendations for the optimal tool for each manufacturing step. If these are not in stock, users can order them directly through integration with the CERATIZIT online shop. This simplifies tool selection, saves procurement time, and improves the software’s ability to optimize the manufacturing strategy for the part.

Operational sequence

Based on the automatically determined stocks, machine tools, manufacturing strategies, and cutting tools, the software calculates the setup, programming, and manufacturing times for individual operational steps, along with the associated costs.

Up to 90% more efficiency – live demos at EMO booth

By using the browser-based software solution Spanflug MAKE, machine shops can reduce their effort for quoting and work preparation by up to 90% and make their manufacturing more efficient. This allows them to not only reduce costs and improve manufacturing sustainability but also to access new customer segments more easily and strengthen their competitive position. Spanflug thus combines all focus themes of this year’s EMO motto, “Innovate Manufacturing”.

Industry professionals and media representatives attending the world’s leading trade fair for production technology are cordially invited to visit Spanflug booth A47 in hall 6 on the Hannover Exhibition Grounds. From September 22-26, 2025, they can experience Spanflug MAKE live and discover the possibilities of AI, digitalization, and automation for manufacturing. There will also be a Spanflug demo station at the CERATIZIT booth B42 in hall 5, where visitors can get hands-on information.