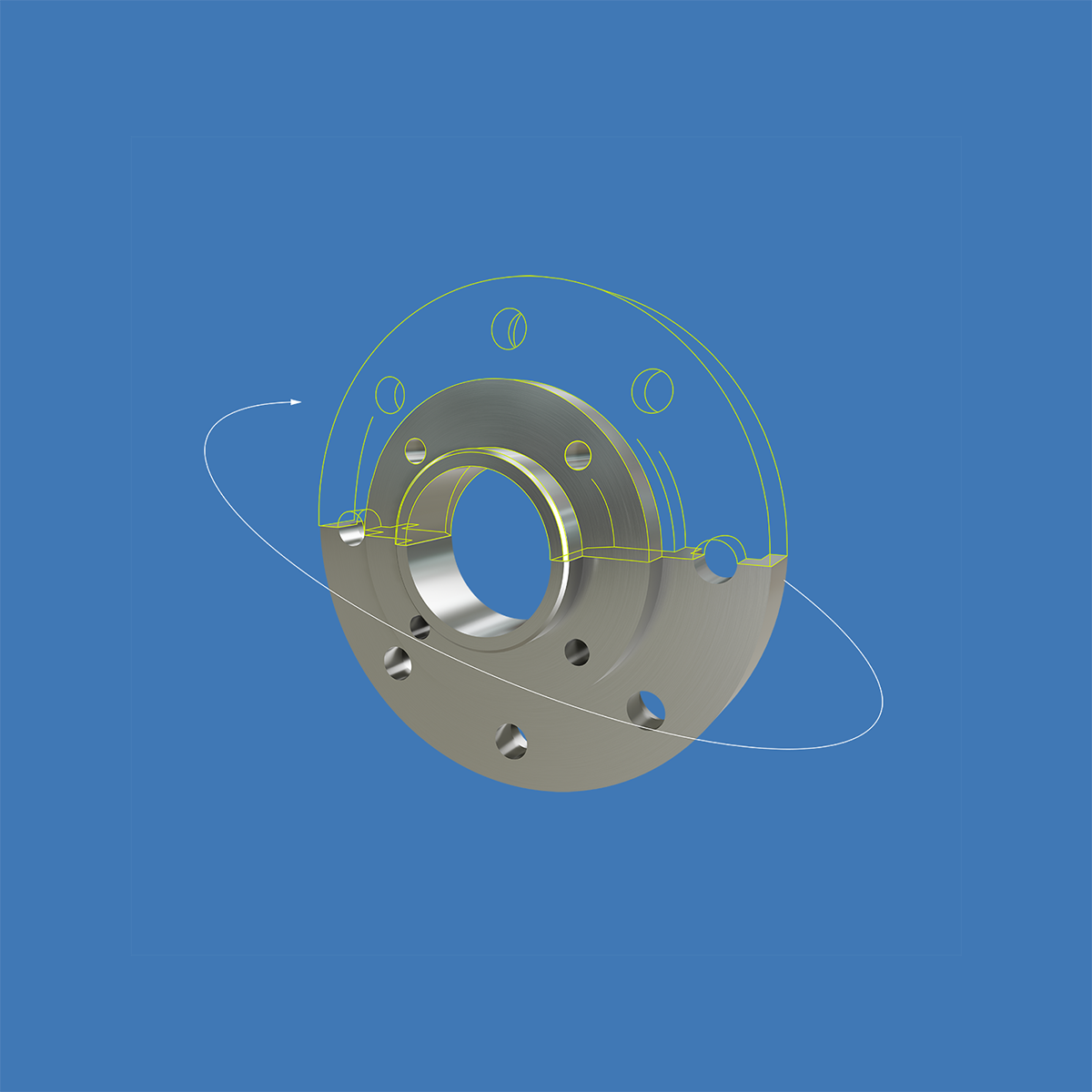

Order turning parts online

At Spanflug, ordering turned parts online is quick and easy. Simply upload your CAD model, receive an instant quote, and place your order with your desired delivery date. We ensure fast and reliable delivery, starting from 5 working days.

How to order turning parts online from Spanflug

You can sign up for free. Then upload the CAD model and technical drawing and select the quantity. The Spanflug algorithm automatically extracts all relevant information from your uploaded data, calculates a price and determines possible delivery dates within a few seconds. You then either place the order directly online with the selected delivery date, or export a PDF quote and order by e-mail.

Customers who trust us

Our technical options for turning parts

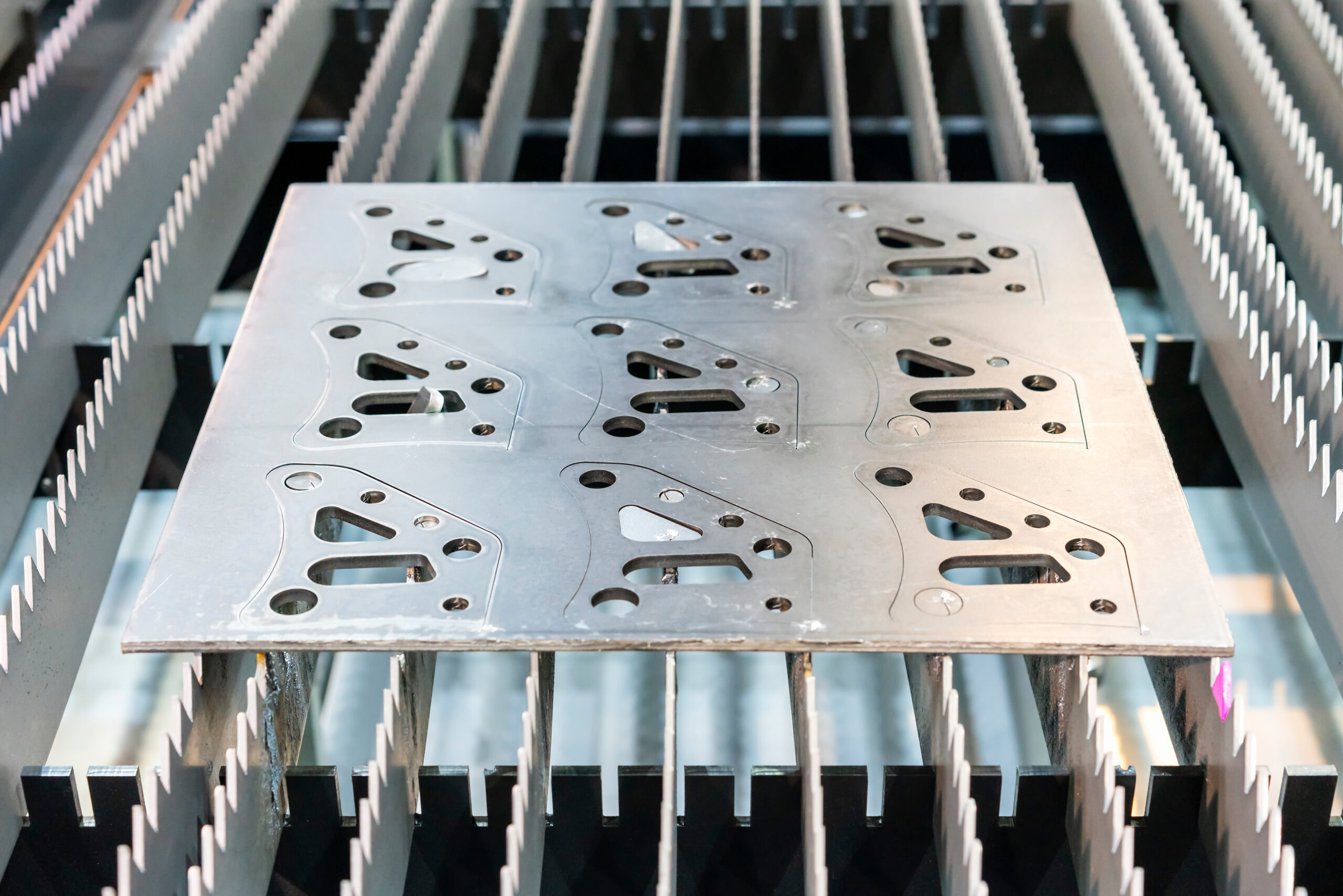

Für folgende Anforderungen erhalten Sie online bei Spanflug BUY innerhalb von Sekunden ein Sofortangebot für Ihre Drehteile:

- Abmessungen:

- Bauteile bis 3.000 mm LängeAbmessungen:

- Bauteile bis 500 mm Durchmesser

- Größere Bauteile auf Anfrage

- Fertigung bis zu einer Genauigkeit von 5 µm

- Oberflächengüte bis zu einem Mittenrauwert von Ra 0,4

- Über 60 Werkstoffe und 30 Nachbehandlungen

- Ab 1 Stück

Für größere oder sehr komplexe Bauteile, Großserien oder Abrufaufträge sowie alle weiteren besonderen Anforderungen nutzen Sie gerne unsere Projektanfrage.

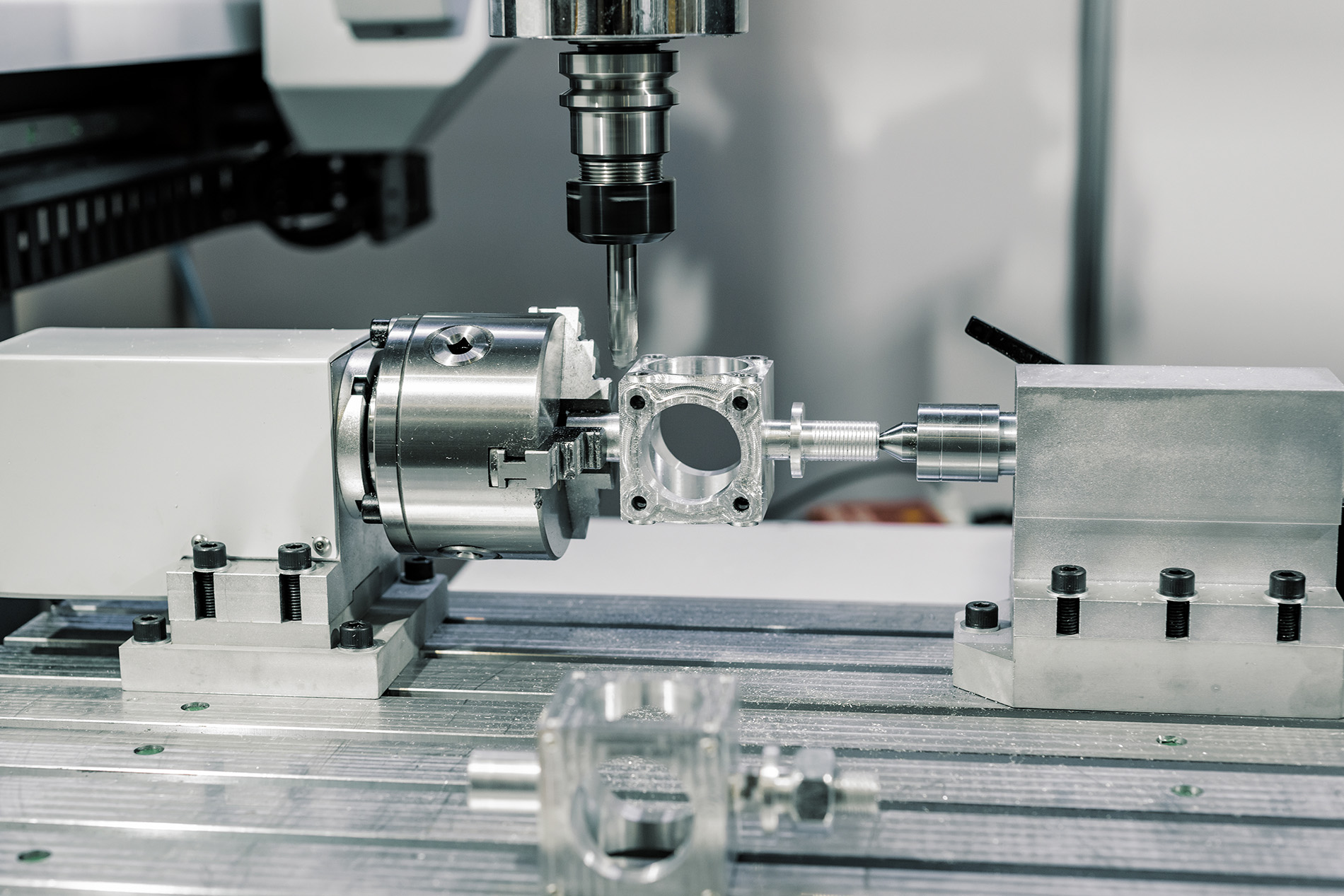

How are turning parts manufactured?

CNC turning parts are manufactured on CNC turning machines through the rotational movement of the workpiece combined with the linear movements of the tools. CNC turning achieves a high level of material removal and is therefore very cost-efficient.

Unlike CNC milling, CNC turning keeps the tool continuously engaged, preventing interrupted cutting conditions. Additionally, CNC turning machines have a simpler mechanical design, making them more cost-effective than milling machines of equivalent performance and size.

In CNC machining, combined machines with driven tools and milling spindles are often used in addition to pure lathes. With such millturning machines, the complete machining of workpieces is possible in a single clamping operation.

Why you should order your turning parts from Spanflug

Fast and uncomplicated ordering process

ISO 9001:2015 certified quality

Fast and reliable manufacturing on over 6,000 machines