CNC turning – fast and reliable

Spanflug is your partner for contract manufacturing in the field of CNC turning. We use our network of over 6,000 CNC machines at ISO 9001:2015-certified partners to manufacture your turning parts quickly and reliably.

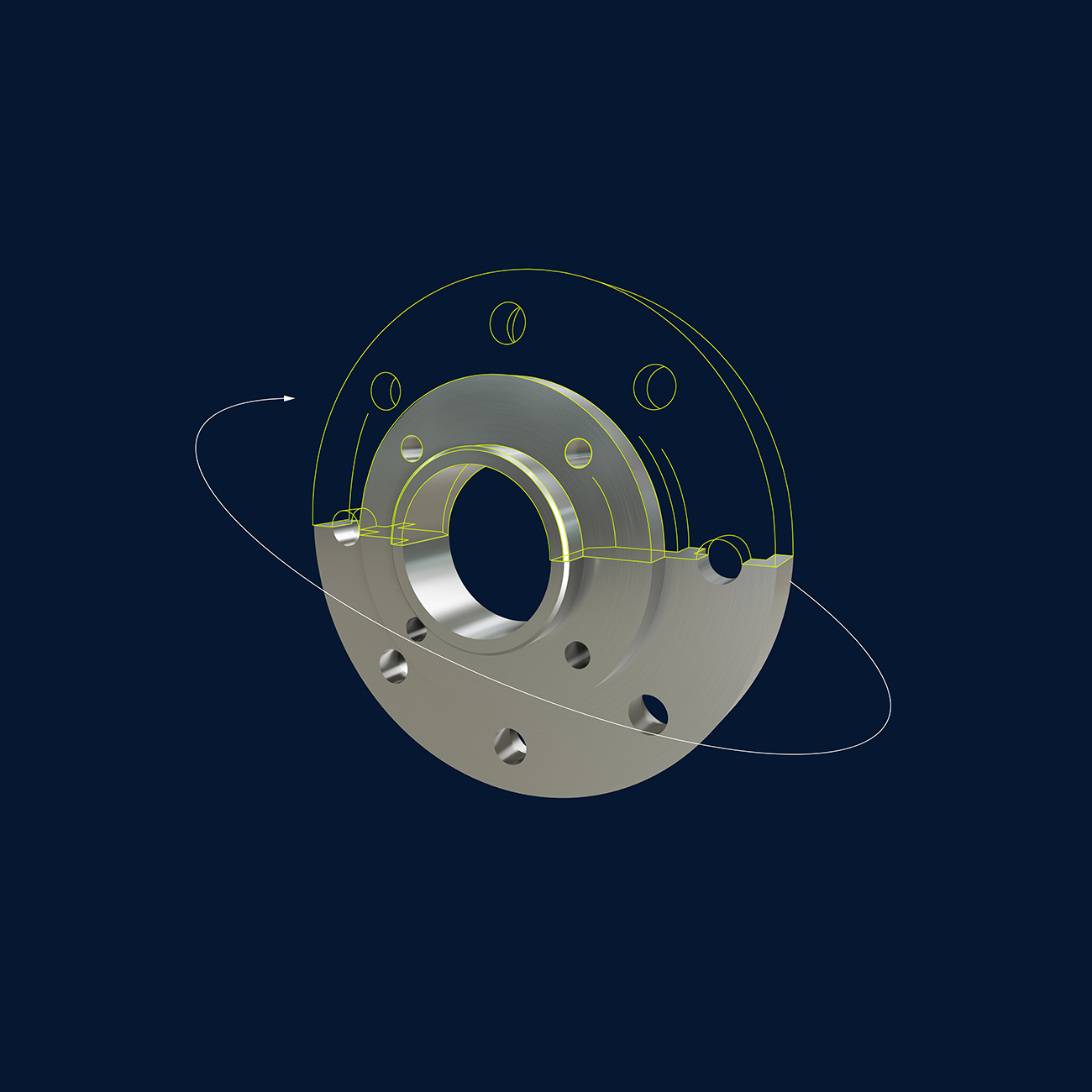

What is CNC turning?

CNC turning is a precise and automated manufacturing process for producing rotationally symmetrical parts. In contrast to manual turning, the control is computer-assisted (CNC = Computerized Numerical Control), which ensures consistently high quality and repeat accuracy.

During turning, a workpiece is clamped in a rotating clamping device (lathe chuck) while a stationary tool removes material. Both simple and highly complex geometries can be manufactured efficiently using precise programmed movements.

How does CNC turning work?

CNC turning parts are manufactured on CNC lathes, where the workpiece rotates while the tools move linearly. This process allows for high material removal rates, making turning highly cost-efficient.

Unlike CNC milling, CNC turning keeps the tool continuously engaged, preventing interrupted cutting conditions. Additionally, CNC turning machines have a simpler mechanical design, making them more cost-effective than milling machines of equivalent performance and size.

In CNC machining, combined machines with driven tools and milling spindles are often used in addition to pure lathes. With such millturning machines, the complete machining of workpieces is possible in a single clamping operation.

Advantages of CNC turning

- High precision and repeat accuracy

- Efficient manufacturing of complex geometries

- Cost-effective production of small, medium and large series

- Automated processes for fast delivery times

Purchasing turning parts quickly and easily – with Spanflug

The procurement of CNC turning parts can be complex and time-consuming – from making inquiries with several contract manufacturers to obtaining quotations and processing orders. With Spanflug BUY you can do this in just a few clicks.

Are you looking for a contract manufacturer specialized in CNC turning?

Which turning parts can Spanflug manufacture for you?

We manufacture your turning parts quickly and reliably, starting from just 5 working days. We offer:

- Turning parts and millturning parts

- Prototypes and individual parts

- Small series

- Standart parts

- Over 60 materials and 30 post-treatments available to order online

CNC turning contract manufacturing: What makes online procurement worthwhile?

Contract manufacturing in CNC turning means that companies outsource the manufacturing of turning parts to specialized suppliers in order to save costs and resources. However, the challenge often lies in selecting the right, appropriately specialized partner, quote preparation and coordination of order processing.

Spanflug eliminates this effort:

- No time-consuming supplier screening – we will find the optimal manufacturing partners for you.

- Reliable quality assurance – all parts meet the highest standards.

- Instant quote online in just a few seconds

- Easy ordering & fast delivery in as little as 5 working days